precise laser engraving

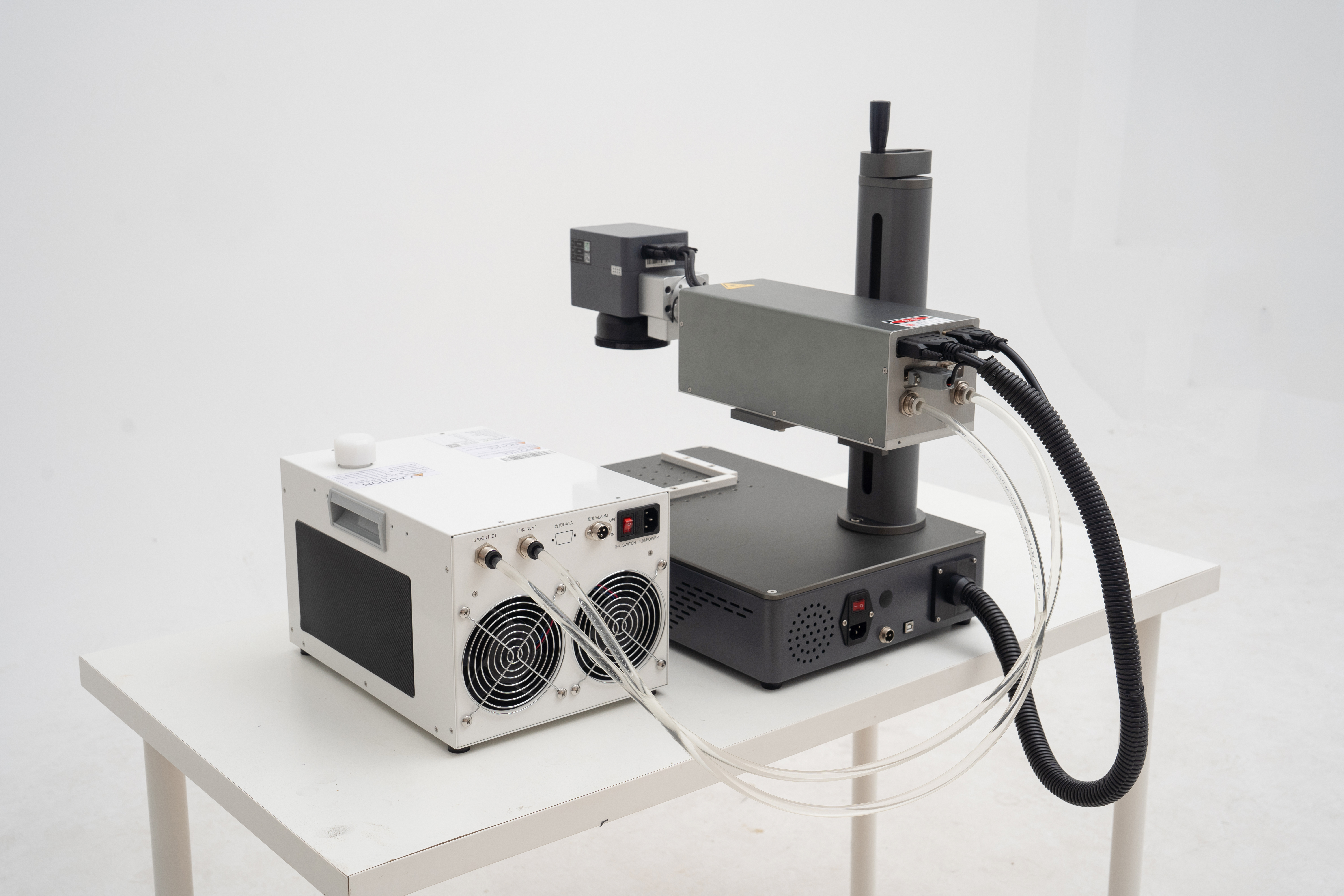

Precise laser engraving represents a cutting-edge manufacturing technology that utilizes focused laser beams to create detailed markings, patterns, and designs on various materials with exceptional accuracy. This advanced process employs computer-controlled laser systems that direct concentrated light energy onto material surfaces, resulting in permanent modifications through controlled material removal or surface alteration. The technology operates by converting electrical energy into coherent light beams that can be precisely manipulated to achieve micrometer-level accuracy in engraving operations. Modern precise laser engraving systems feature sophisticated beam control mechanisms, variable power settings, and high-resolution positioning systems that enable operators to create intricate designs with remarkable consistency. The main functions of precise laser engraving include surface marking for identification purposes, decorative pattern creation, component serialization, and quality control marking across manufacturing processes. Technological features encompass adjustable laser power output, multi-axis positioning systems, real-time monitoring capabilities, and automated material handling integration. These systems support various engraving depths, from shallow surface marking to deep material removal, depending on application requirements. The technology accommodates diverse materials including metals, plastics, ceramics, glass, wood, leather, and composite materials, making it versatile for numerous industrial applications. Precise laser engraving finds extensive use in automotive manufacturing for part identification, electronics industry for component marking, medical device production for traceability, aerospace applications for critical part labeling, jewelry creation for personalization, and promotional product customization. The process maintains exceptional repeatability, enabling mass production while preserving individual design integrity. Environmental considerations make precise laser engraving attractive as it produces minimal waste, requires no chemical consumables, and operates with reduced environmental impact compared to traditional engraving methods.

EN

EN

AR

AR

FR

FR

DE

DE

JA

JA

KO

KO

RU

RU

ES

ES