metal marking laser

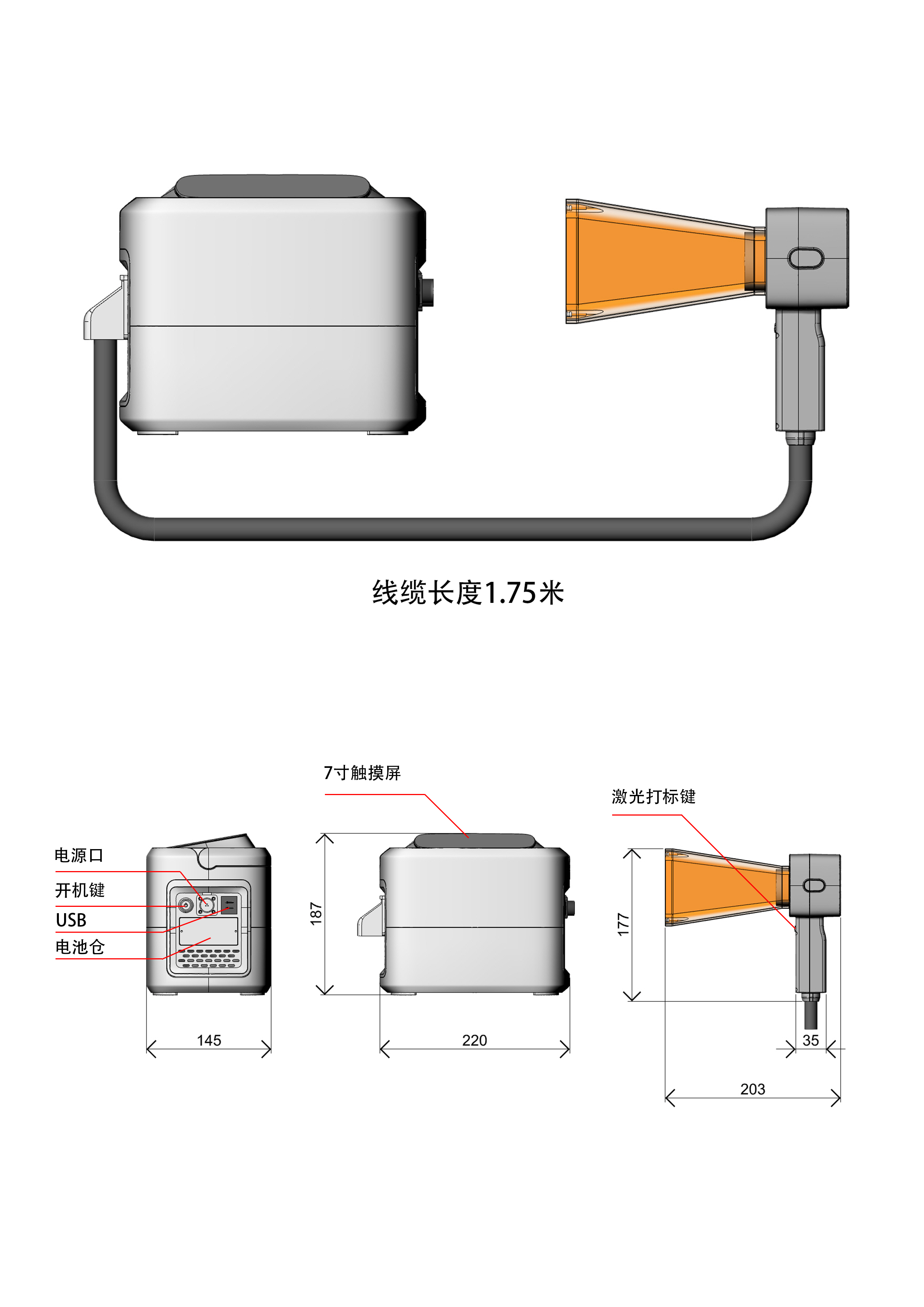

A metal marking laser represents cutting-edge technology designed to create permanent, precise markings on various metallic surfaces with exceptional accuracy and efficiency. This sophisticated system utilizes concentrated laser beams to etch, engrave, or mark different types of metals including stainless steel, aluminum, titanium, brass, copper, and carbon steel. The metal marking laser operates through a highly controlled process where focused light energy creates localized heating, resulting in material removal, color changes, or surface modifications that produce visible, durable markings. Modern metal marking laser systems incorporate advanced fiber laser technology, delivering superior beam quality and consistent performance across diverse applications. These systems feature computer-controlled precision positioning, enabling operators to create complex designs, serial numbers, barcodes, logos, and text with remarkable detail and repeatability. The technology supports both shallow surface marking and deeper engraving capabilities, allowing users to customize marking depth based on specific requirements. Contemporary metal marking laser equipment includes user-friendly software interfaces that streamline the marking process, enabling operators to import designs, adjust parameters, and execute marking operations with minimal training. The systems typically offer variable pulse frequencies, power settings, and marking speeds, providing flexibility to optimize results for different metal types and marking requirements. Advanced metal marking laser systems also feature automated focusing mechanisms, ensuring consistent marking quality regardless of surface variations or workpiece positioning. Safety features are integrated throughout these systems, including protective enclosures, interlock systems, and emission controls that comply with international laser safety standards. The versatility of metal marking laser technology extends to handling various part sizes and shapes, from small precision components to larger industrial parts, making it suitable for both high-volume production environments and specialized custom applications.

EN

EN

AR

AR

FR

FR

DE

DE

JA

JA

KO

KO

RU

RU

ES

ES