types of laser marking

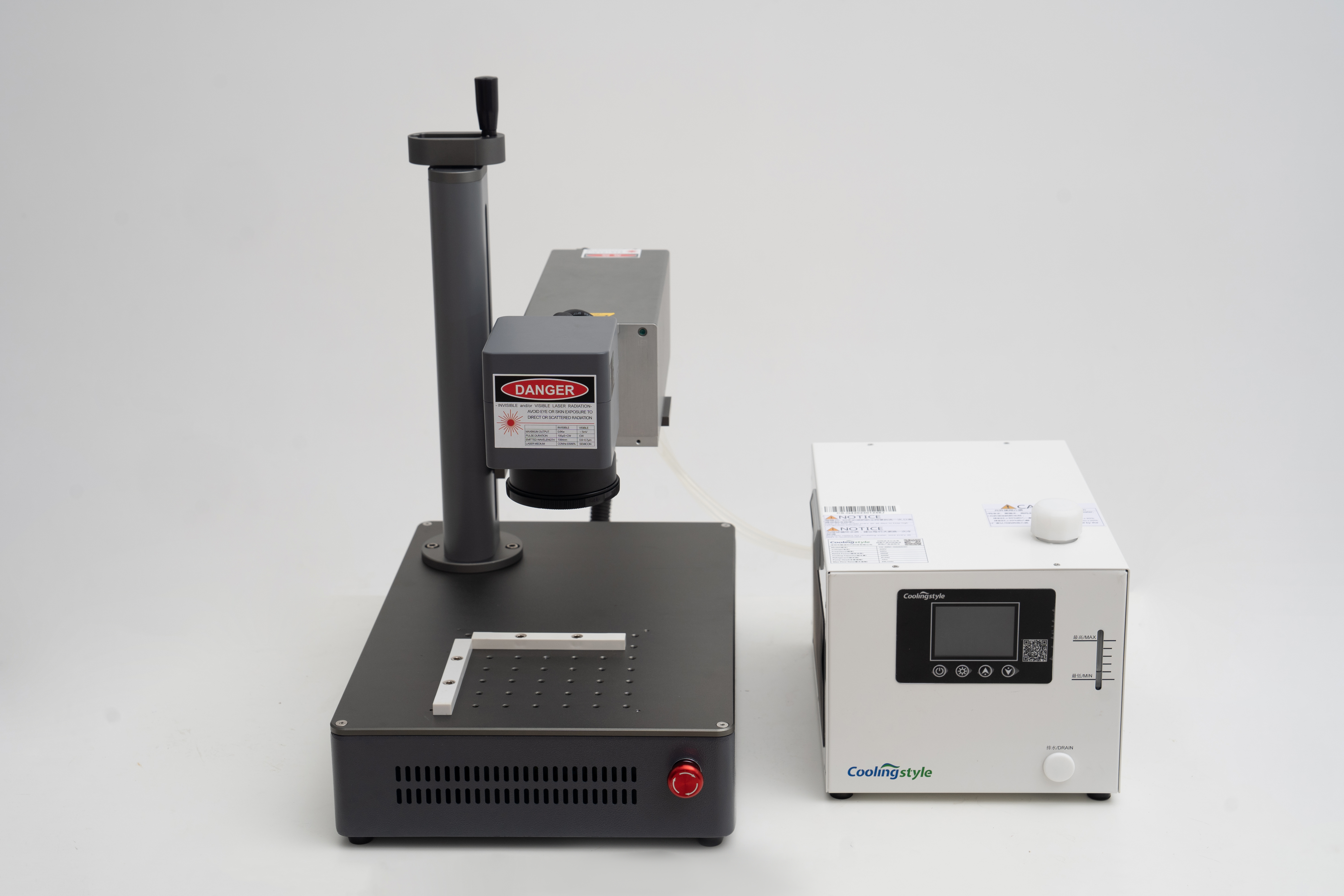

The types of laser marking represent a revolutionary advancement in industrial identification and manufacturing processes, offering unparalleled precision and versatility across numerous applications. Laser marking technology encompasses several distinct methodologies, each designed to meet specific requirements for permanent material identification. The primary types of laser marking include fiber laser marking, CO2 laser marking, UV laser marking, and diode laser marking, each utilizing different wavelengths and mechanisms to achieve optimal results on various substrates. Fiber laser marking operates at wavelengths around 1064nm, making it exceptionally effective for metals, plastics, and engineered materials. This technology delivers high-speed processing with remarkable precision, creating permanent marks that withstand harsh environmental conditions. CO2 laser marking utilizes wavelengths of 10.6 micrometers, proving ideal for organic materials, ceramics, glass, and certain plastics. The technology excels in creating deep engravings and surface modifications with excellent contrast and readability. UV laser marking operates at shorter wavelengths, typically 355nm, enabling cold processing that prevents thermal damage to sensitive materials. This approach proves particularly valuable for electronics, medical devices, and premium consumer goods where heat-affected zones must be minimized. Diode laser marking systems offer cost-effective solutions for specific applications, particularly in packaging and light-duty industrial marking requirements. The technological features of these types of laser marking include computer-controlled beam positioning, variable power settings, adjustable pulse frequencies, and sophisticated software integration. These systems integrate seamlessly with production lines, enabling real-time marking during manufacturing processes. Applications span automotive component identification, medical device traceability, electronics serialization, aerospace part marking, jewelry engraving, and packaging date coding. The types of laser marking continue evolving with advancing technology, incorporating artificial intelligence, improved beam quality, and enhanced automation capabilities to meet growing industrial demands for permanent, high-quality identification solutions.

EN

EN

AR

AR

FR

FR

DE

DE

JA

JA

KO

KO

RU

RU

ES

ES