laser fiber marking

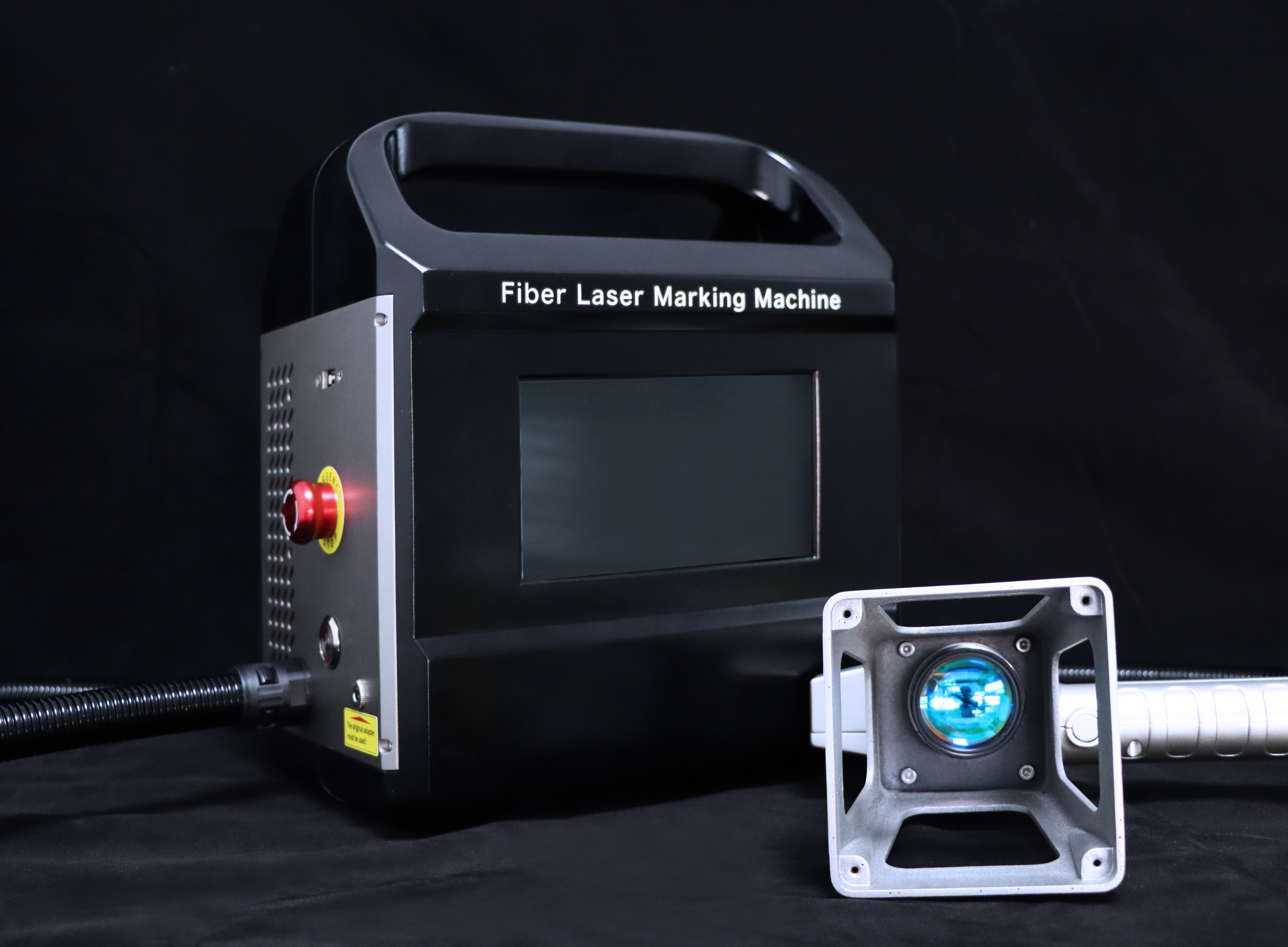

Laser fiber marking represents a cutting-edge industrial technology that utilizes focused laser beams transmitted through optical fibers to create permanent marks on various materials. This advanced marking system employs fiber laser technology to generate concentrated light energy that precisely etches, engraves, or ablates surface materials without physical contact. The laser fiber marking process operates by directing high-intensity laser pulses through fiber optic cables to a marking head, which focuses the beam onto the target surface with exceptional accuracy. The main functions of laser fiber marking include creating text, logos, barcodes, QR codes, serial numbers, and intricate designs on diverse materials ranging from metals and plastics to ceramics and glass. This technology excels in producing high-contrast, permanent markings that resist wear, corrosion, and environmental factors. The technological features of laser fiber marking systems include computer-controlled precision, adjustable power settings, variable marking speeds, and programmable pattern capabilities. Modern laser fiber marking equipment integrates seamlessly with manufacturing lines through automated control systems and real-time monitoring features. The applications span numerous industries including automotive manufacturing for part identification, medical device production for traceability requirements, electronics manufacturing for component labeling, aerospace industry for critical part marking, and jewelry creation for detailed engraving work. Laser fiber marking technology offers superior beam quality, excellent thermal stability, and minimal maintenance requirements compared to traditional marking methods. The system's compact design and energy efficiency make it ideal for both high-volume production environments and specialized custom applications, delivering consistent results across extended operating periods while maintaining exceptional marking quality and precision standards.

EN

EN

AR

AR

FR

FR

DE

DE

JA

JA

KO

KO

RU

RU

ES

ES