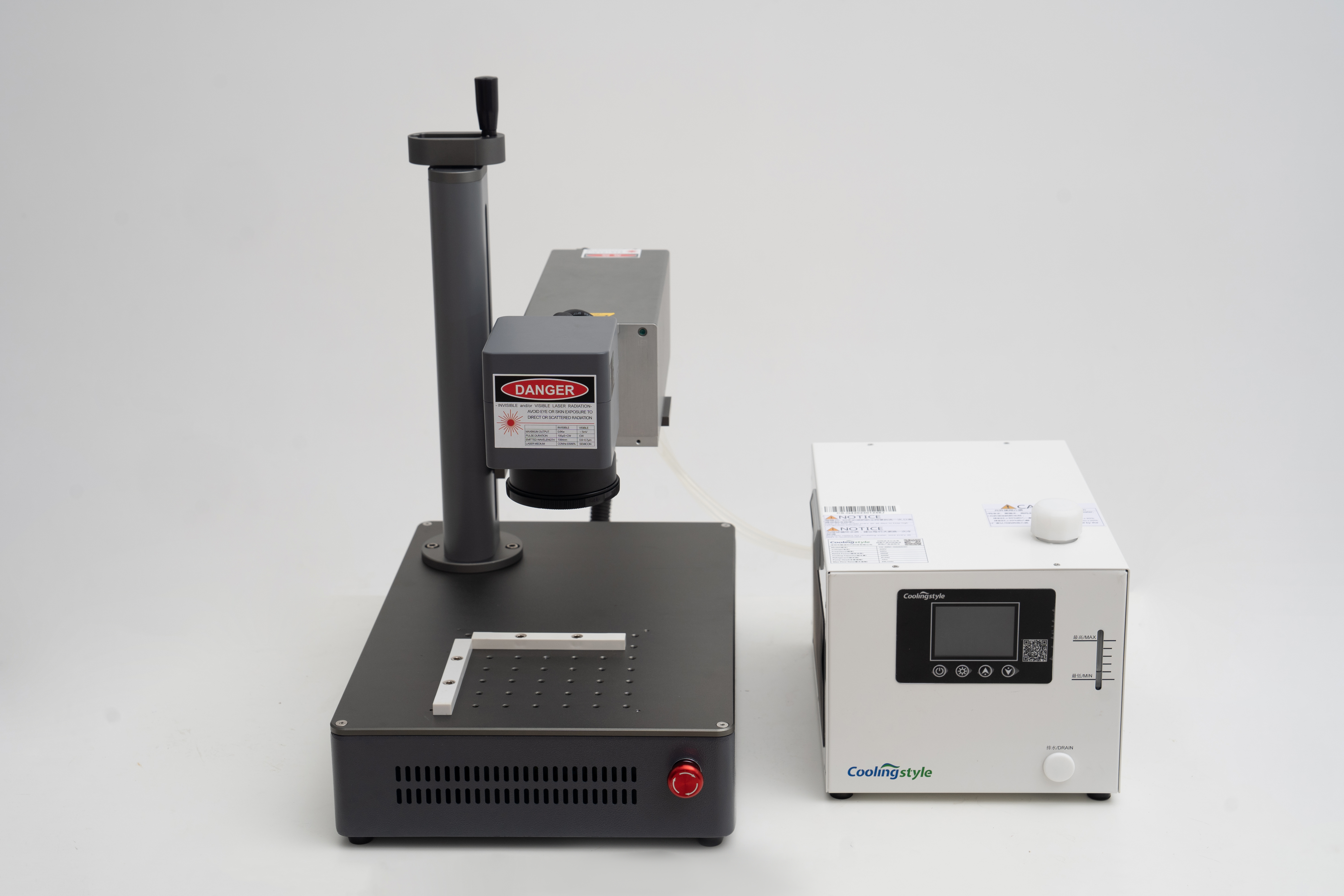

laser marking rotary

A laser marking rotary represents a sophisticated advancement in industrial marking technology, designed to enhance the precision and efficiency of cylindrical object marking processes. This specialized equipment combines high-powered laser systems with precision rotational mechanisms, enabling manufacturers to create permanent, high-quality markings on round or cylindrical products with exceptional accuracy. The laser marking rotary operates by securing objects in a rotating chuck while the laser beam creates detailed engravings, text, logos, or barcodes on the surface as the item spins. This technology supports various materials including metals, plastics, ceramics, and composites, making it versatile for numerous industrial applications. The main functions encompass automated rotation control, precise positioning systems, and integrated laser power management that ensures consistent marking quality across the entire circumference of objects. Key technological features include programmable rotation speeds, multi-axis positioning capabilities, and advanced software integration that allows for complex pattern creation. The system typically incorporates safety protocols, real-time monitoring capabilities, and quality control mechanisms that detect marking defects instantly. Modern laser marking rotary systems feature user-friendly interfaces, allowing operators to program marking parameters easily while maintaining production efficiency. The equipment supports batch processing capabilities, enabling continuous operation for high-volume manufacturing environments. Additionally, these systems often include automatic loading and unloading mechanisms, reducing manual intervention requirements. The precision engineering ensures minimal material waste while maximizing throughput rates. Applications span across automotive component marking, medical device identification, aerospace part traceability, and consumer goods branding. The laser marking rotary has become indispensable in industries requiring permanent identification solutions that withstand harsh environmental conditions while maintaining readability throughout the product lifecycle.

EN

EN

AR

AR

FR

FR

DE

DE

JA

JA

KO

KO

RU

RU

ES

ES