laser marking types

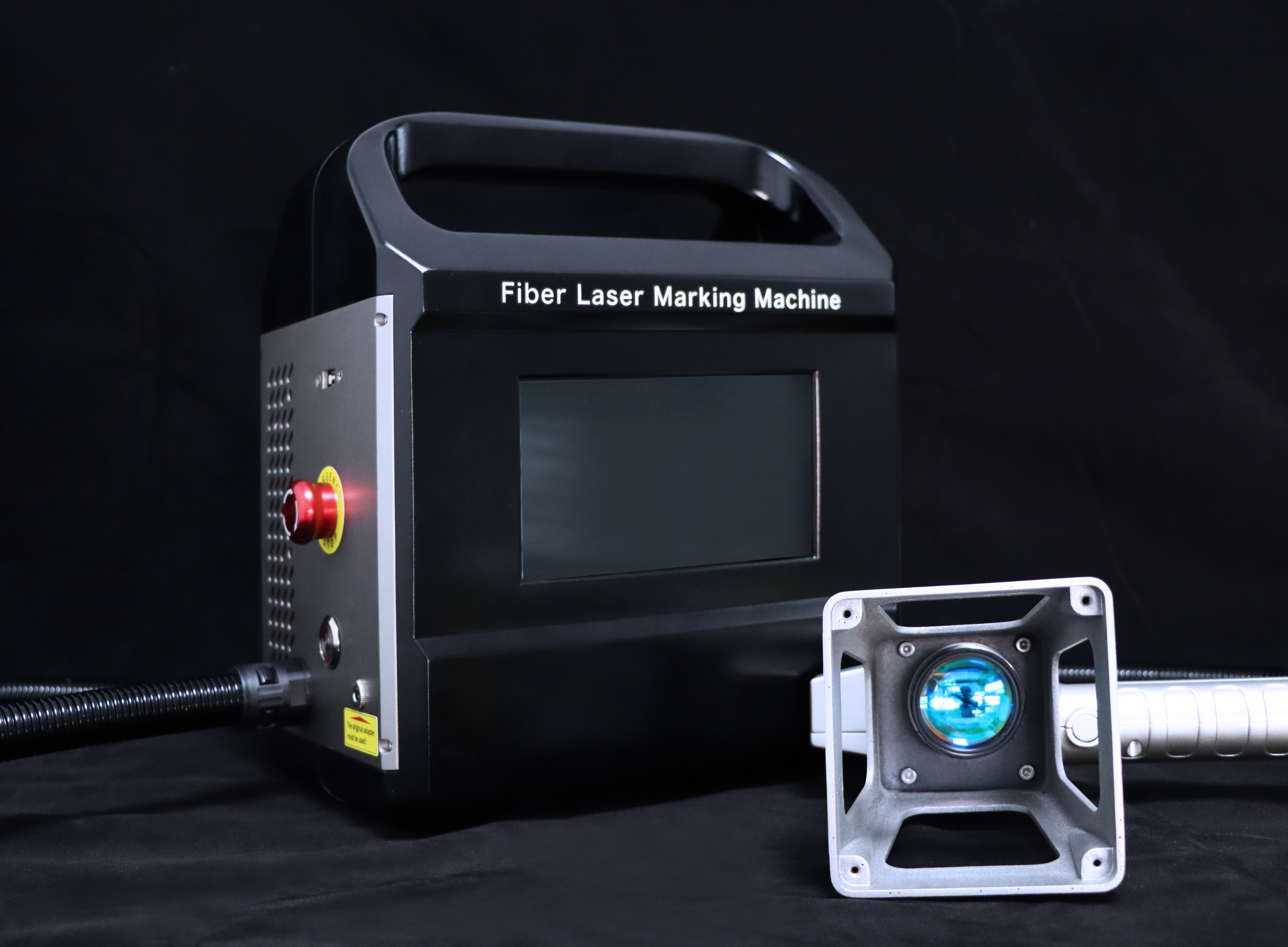

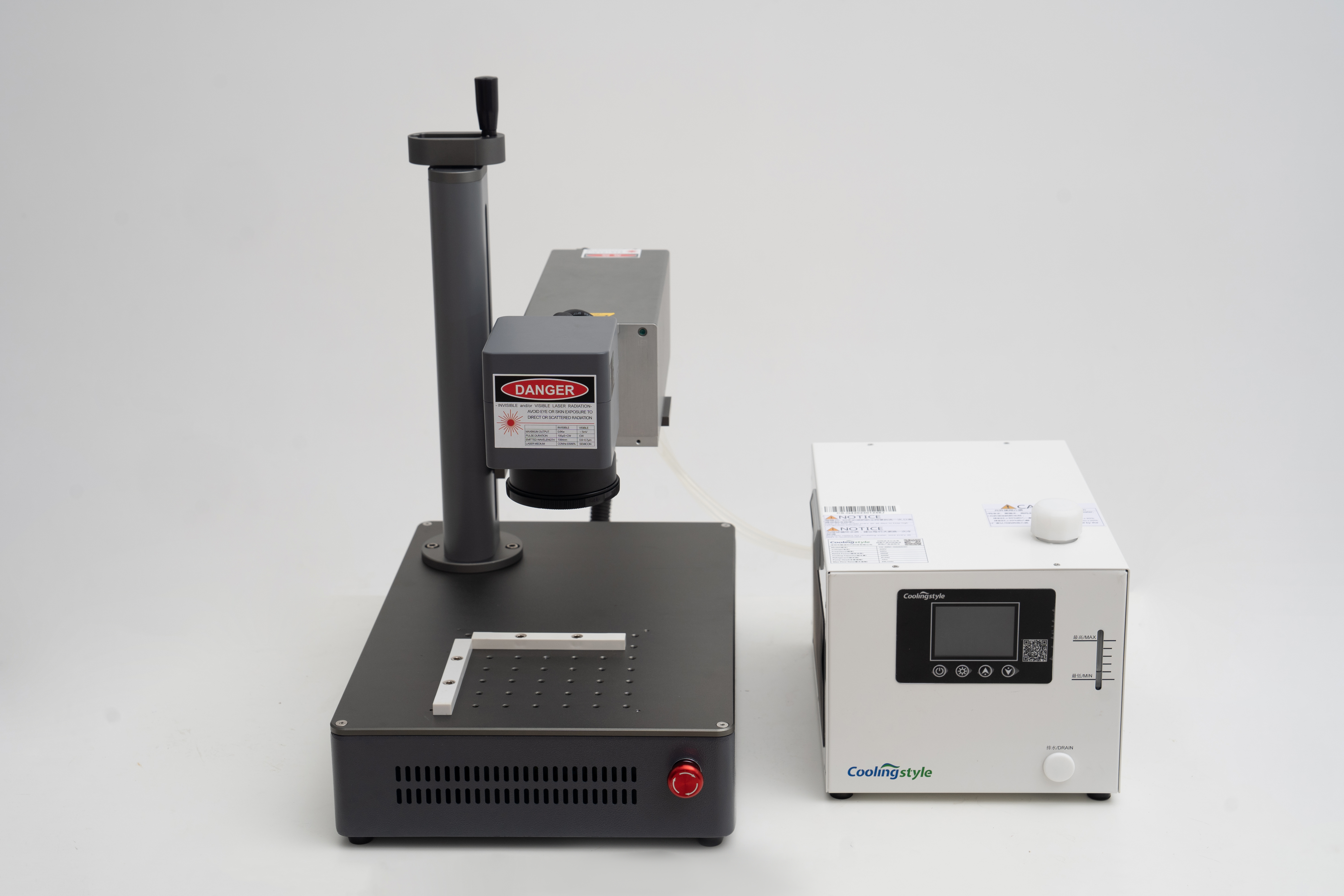

Laser marking types represent cutting-edge engraving and identification solutions that utilize focused light beams to create permanent, high-quality marks on various materials. These sophisticated systems employ different laser technologies, including fiber lasers, CO2 lasers, and UV lasers, each designed for specific material compatibility and marking requirements. The main functions of laser marking types encompass precise surface etching, deep engraving, color changing, and material removal processes that produce durable identification marks, barcodes, serial numbers, logos, and decorative patterns. The technological features of modern laser marking types include computer-controlled precision, adjustable power settings, variable marking speeds, and multi-axis positioning systems that ensure consistent results across production runs. These systems integrate seamlessly with manufacturing workflows through automated feeding mechanisms, conveyor belt compatibility, and real-time quality monitoring capabilities. Applications for laser marking types span numerous industries, including automotive manufacturing for component identification, medical device production for regulatory compliance marking, electronics assembly for circuit board labeling, aerospace components for traceability requirements, and consumer goods for brand identification. The pharmaceutical industry relies heavily on laser marking types for drug packaging authentication and anti-counterfeiting measures. Additionally, jewelry manufacturers utilize these systems for intricate design work and personalization services. The food and beverage sector employs laser marking types for expiration date coding and lot number tracking on packaging materials. Construction and industrial equipment manufacturers depend on these technologies for safety compliance marking and operational instruction labeling. The versatility of laser marking types extends to educational institutions for laboratory equipment identification and research facilities for sample tracking systems, demonstrating their broad applicability across diverse sectors requiring permanent, legible, and tamper-resistant marking solutions.

EN

EN

AR

AR

FR

FR

DE

DE

JA

JA

KO

KO

RU

RU

ES

ES