automatic welding & supply

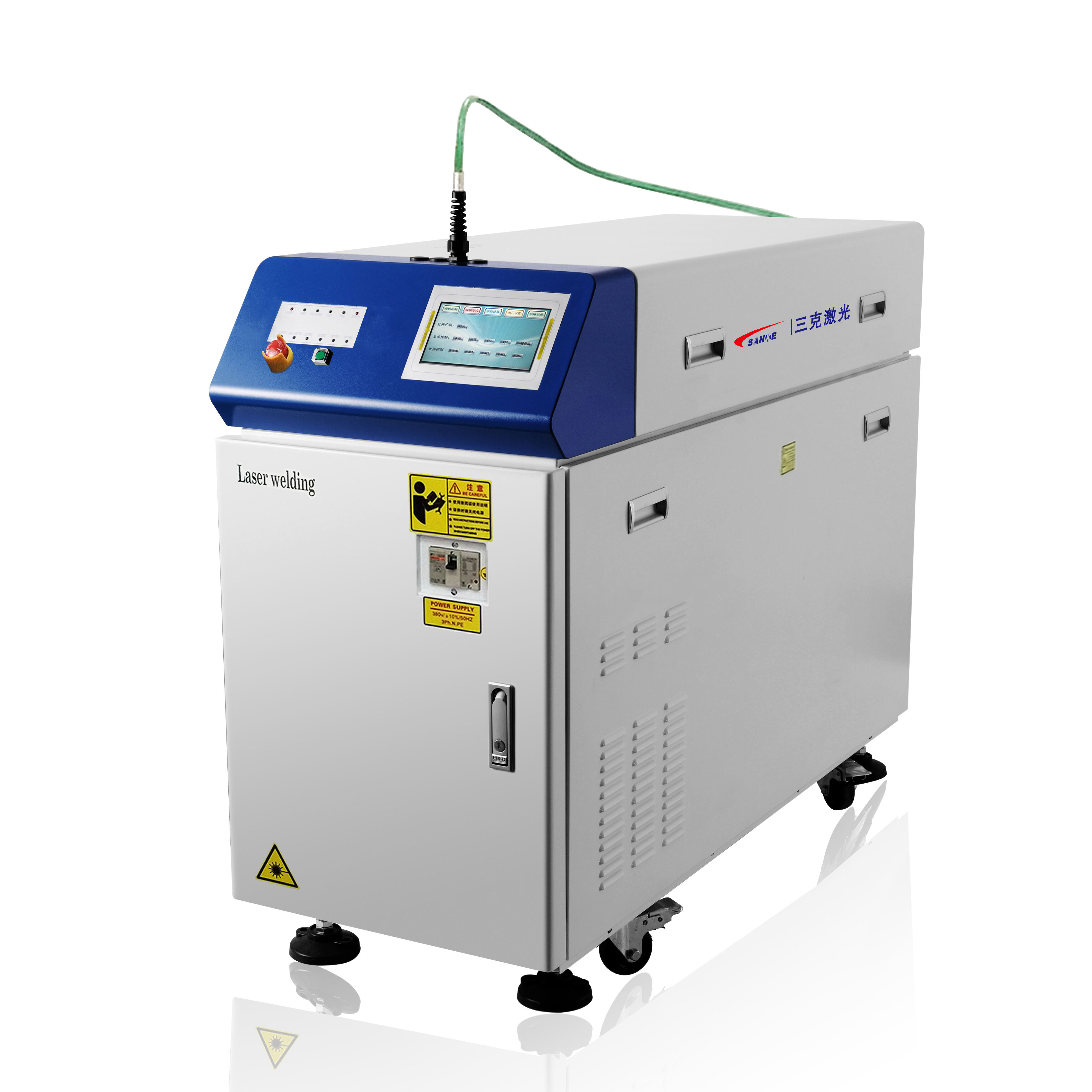

Automatic welding & supply represents a revolutionary advancement in modern manufacturing technology, transforming traditional welding processes through sophisticated automation systems. This comprehensive solution integrates cutting-edge robotics, intelligent control systems, and precision material handling equipment to deliver consistent, high-quality welding results across diverse industrial applications. The automatic welding & supply system combines advanced welding technologies with automated material feeding mechanisms, creating seamless production workflows that significantly enhance operational efficiency. At its core, the system utilizes computer-controlled welding torches, programmable motion controllers, and adaptive sensing technologies to execute complex welding patterns with extraordinary precision. The technological features include real-time arc monitoring, automatic wire feeding systems, gas flow regulation, and intelligent seam tracking capabilities that ensure optimal weld penetration and quality. Advanced sensors continuously monitor welding parameters such as voltage, current, travel speed, and wire feed rate, making instantaneous adjustments to maintain consistent results throughout the entire welding process. The automatic welding & supply system incorporates sophisticated vision systems that can detect joint variations, adjust welding parameters accordingly, and compensate for material inconsistencies in real-time. Applications span across automotive manufacturing, shipbuilding, construction, aerospace, pipeline installation, and heavy machinery production. In automotive industries, these systems handle chassis welding, body panel assembly, and exhaust system fabrication with remarkable speed and accuracy. Shipbuilding operations utilize automatic welding & supply for hull construction, deck plating, and structural component assembly, where consistent weld quality is paramount for safety and structural integrity. Construction projects benefit from automated welding in steel frame assembly, bridge construction, and building infrastructure development. The system's versatility allows it to handle various materials including carbon steel, stainless steel, aluminum alloys, and exotic metals, making it indispensable for modern manufacturing environments that demand precision, reliability, and efficiency in their welding operations.

EN

EN

AR

AR

FR

FR

DE

DE

JA

JA

KO

KO

RU

RU

ES

ES