automated robotic welding

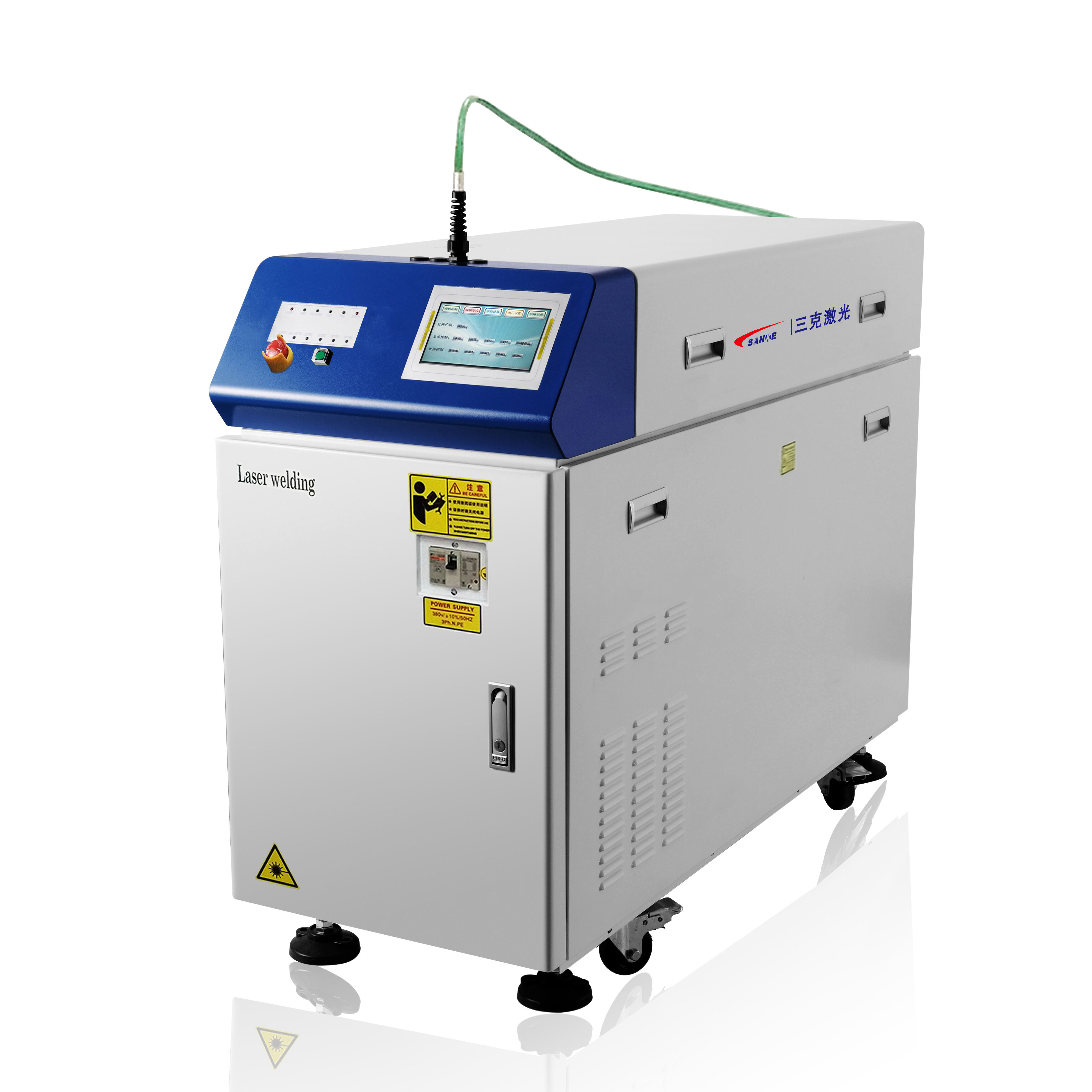

Automated robotic welding represents a revolutionary advancement in manufacturing technology that combines precision robotics with sophisticated welding capabilities to deliver consistent, high-quality results. This cutting-edge system utilizes programmable robotic arms equipped with advanced welding torches, sensors, and control systems to perform complex welding operations with minimal human intervention. The main functions of automated robotic welding encompass precise material joining, seam tracking, quality monitoring, and adaptive control adjustments throughout the welding process. These systems excel at executing repetitive welding tasks while maintaining exceptional accuracy and repeatability that surpasses traditional manual welding methods. The technological features include multi-axis robotic manipulators that provide unlimited positioning flexibility, advanced vision systems for real-time monitoring, integrated cooling systems for optimal performance, and sophisticated software that enables complex programming and path planning. Modern automated robotic welding systems incorporate artificial intelligence algorithms that learn from previous operations and continuously optimize welding parameters for enhanced performance. Applications span numerous industries including automotive manufacturing, aerospace production, shipbuilding, construction equipment fabrication, and heavy machinery assembly. In automotive plants, these systems handle chassis welding, body panel assembly, and exhaust system manufacturing with remarkable speed and precision. Aerospace applications focus on critical structural components where quality and consistency are paramount. The technology accommodates various welding processes including MIG, TIG, spot welding, and laser welding, making it versatile for different material types and thickness requirements. Integration capabilities allow seamless connection with existing production lines, material handling systems, and quality control networks. The automated robotic welding process begins with precise workpiece positioning, followed by programmed torch movement along predetermined paths, continuous monitoring of welding parameters, and real-time adjustments based on sensor feedback to ensure optimal weld quality throughout the entire operation.

EN

EN

AR

AR

FR

FR

DE

DE

JA

JA

KO

KO

RU

RU

ES

ES