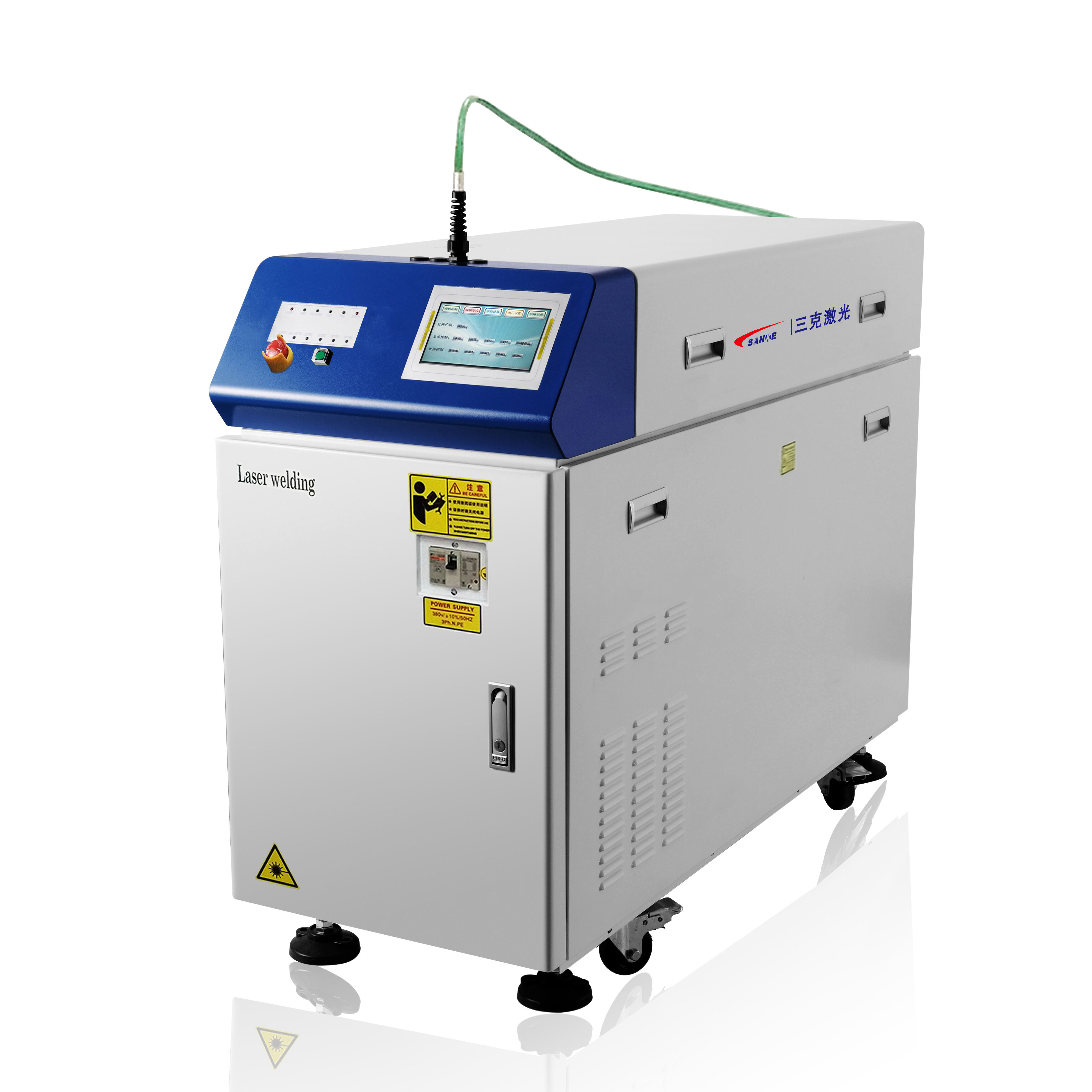

automatic welding equipment

Automatic welding equipment represents a revolutionary advancement in metal fabrication technology that transforms traditional manual welding processes into precise, consistent, and highly efficient operations. This sophisticated machinery integrates advanced robotics, computer-controlled systems, and precision welding technologies to deliver superior results across diverse industrial applications. The automatic welding equipment operates through programmable control systems that manage welding parameters including arc voltage, current flow, travel speed, and wire feed rates with exceptional accuracy. These systems incorporate multiple welding processes such as MIG, TIG, plasma arc, and resistance welding, providing versatility for various material types and thicknesses. The equipment features advanced sensors and monitoring systems that continuously track weld quality, detecting potential defects and making real-time adjustments to maintain optimal performance standards. Modern automatic welding equipment includes sophisticated positioning systems with multi-axis movement capabilities, enabling complex weld geometries and hard-to-reach joint configurations. The technology incorporates intelligent programming interfaces that allow operators to create, store, and recall welding programs for different projects, significantly reducing setup times and ensuring consistent reproduction of successful weld parameters. Safety features are extensively integrated, including protective enclosures, automatic shutdown systems, and comprehensive monitoring protocols that protect both operators and equipment. The automatic welding equipment supports various material combinations including steel, aluminum, stainless steel, and exotic alloys, making it suitable for aerospace, automotive, construction, shipbuilding, and manufacturing industries. These systems deliver exceptional precision with tolerances measured in fractions of millimeters, ensuring structural integrity and meeting stringent quality standards required in critical applications.

EN

EN

AR

AR

FR

FR

DE

DE

JA

JA

KO

KO

RU

RU

ES

ES