automated laser welding machine

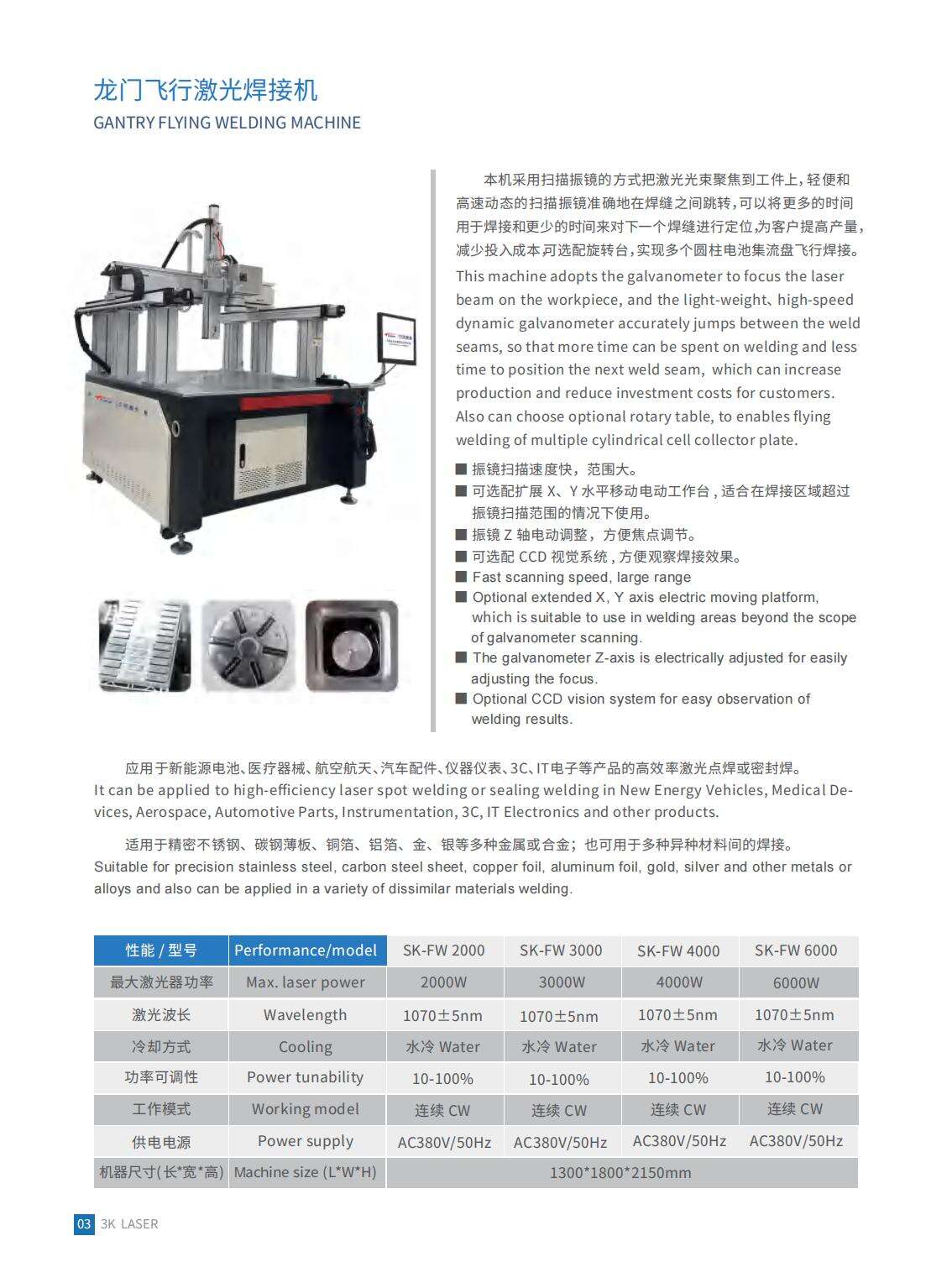

An automated laser welding machine represents cutting-edge manufacturing technology that revolutionizes how industries approach precision joining processes. This sophisticated equipment combines high-powered laser technology with computer-controlled automation systems to deliver consistent, high-quality welding results across diverse materials and applications. The automated laser welding machine operates by generating a concentrated beam of coherent light that creates localized heating, melting the workpiece materials to form strong, permanent joints. The main functions of an automated laser welding machine encompass precise material joining, seam tracking, quality monitoring, and process documentation. These systems excel in creating narrow, deep penetration welds with minimal heat-affected zones, ensuring structural integrity while maintaining aesthetic appeal. The technological features include programmable welding parameters, real-time process monitoring, adaptive control systems, and integrated safety protocols. Advanced automated laser welding machine models incorporate vision systems for joint recognition, robotic positioning arms for complex geometries, and sophisticated cooling systems for continuous operation. The applications span automotive manufacturing, aerospace components, medical device production, electronics assembly, and precision tooling. In automotive sectors, automated laser welding machine technology enables the joining of dissimilar materials, creating lightweight yet strong vehicle structures. Aerospace applications benefit from the precision and repeatability that automated laser welding machine systems provide when working with critical components requiring exceptional quality standards. Medical device manufacturers rely on automated laser welding machine capabilities for creating hermetic seals and biocompatible joints. The technology proves invaluable in electronics where component miniaturization demands extremely precise welding capabilities. Industrial tooling applications leverage automated laser welding machine systems for creating durable cutting tools and specialized fixtures that withstand demanding operational conditions.

EN

EN

AR

AR

FR

FR

DE

DE

JA

JA

KO

KO

RU

RU

ES

ES