laser transmission welding

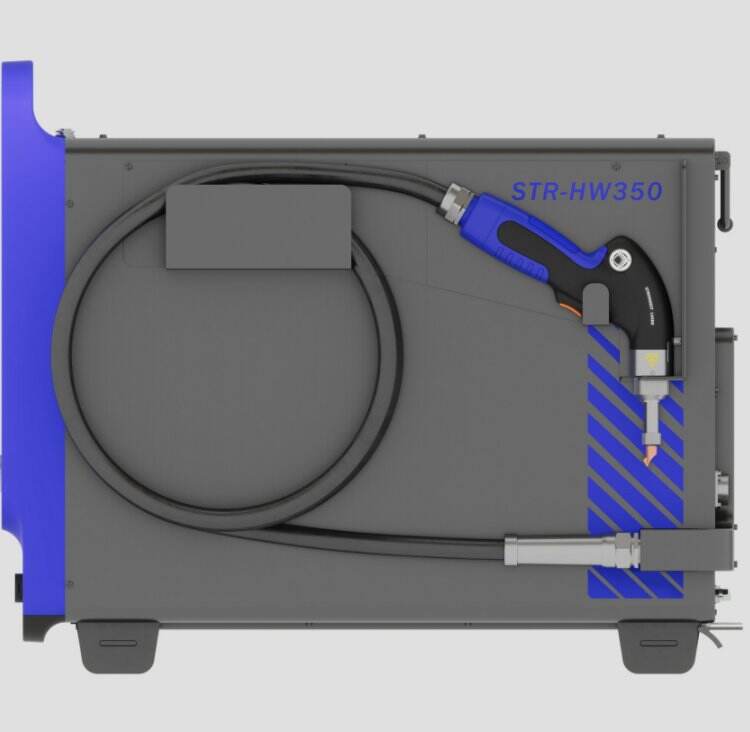

Laser transmission welding represents a revolutionary joining technology that utilizes focused laser energy to create permanent bonds between thermoplastic materials. This innovative process employs a near-infrared laser beam that passes through a transparent or translucent material to reach an absorbing layer beneath, generating localized heat that melts and fuses the materials together. The technology operates on the principle of selective heating, where one component remains transparent to the laser wavelength while the other absorbs the energy, creating a controlled melting zone at the interface. The laser transmission welding process offers exceptional precision, allowing manufacturers to create strong, hermetic seals without mechanical fasteners or adhesives. The system typically consists of a laser source, beam delivery optics, positioning equipment, and clamping fixtures that hold components in precise alignment during the welding cycle. Modern laser transmission welding systems incorporate advanced controls that monitor temperature, pressure, and beam positioning to ensure consistent weld quality. The process parameters can be precisely adjusted to accommodate different material combinations, thicknesses, and joint geometries. Unlike traditional welding methods that require external heat sources or chemical bonding agents, laser transmission welding creates molecular-level bonds that maintain the integrity of the base materials. The technology supports various joint configurations including lap joints, butt joints, and complex three-dimensional geometries. Quality control systems integrated into laser transmission welding equipment provide real-time monitoring of weld parameters, enabling immediate detection of process variations. The non-contact nature of the laser beam eliminates tool wear and reduces maintenance requirements compared to conventional joining methods. This technology has gained widespread acceptance across industries due to its ability to produce clean, precise welds with minimal heat-affected zones, making it ideal for applications requiring high strength, aesthetic appeal, and reliable performance in demanding environments.

EN

EN

AR

AR

FR

FR

DE

DE

JA

JA

KO

KO

RU

RU

ES

ES