laser hybrid welding

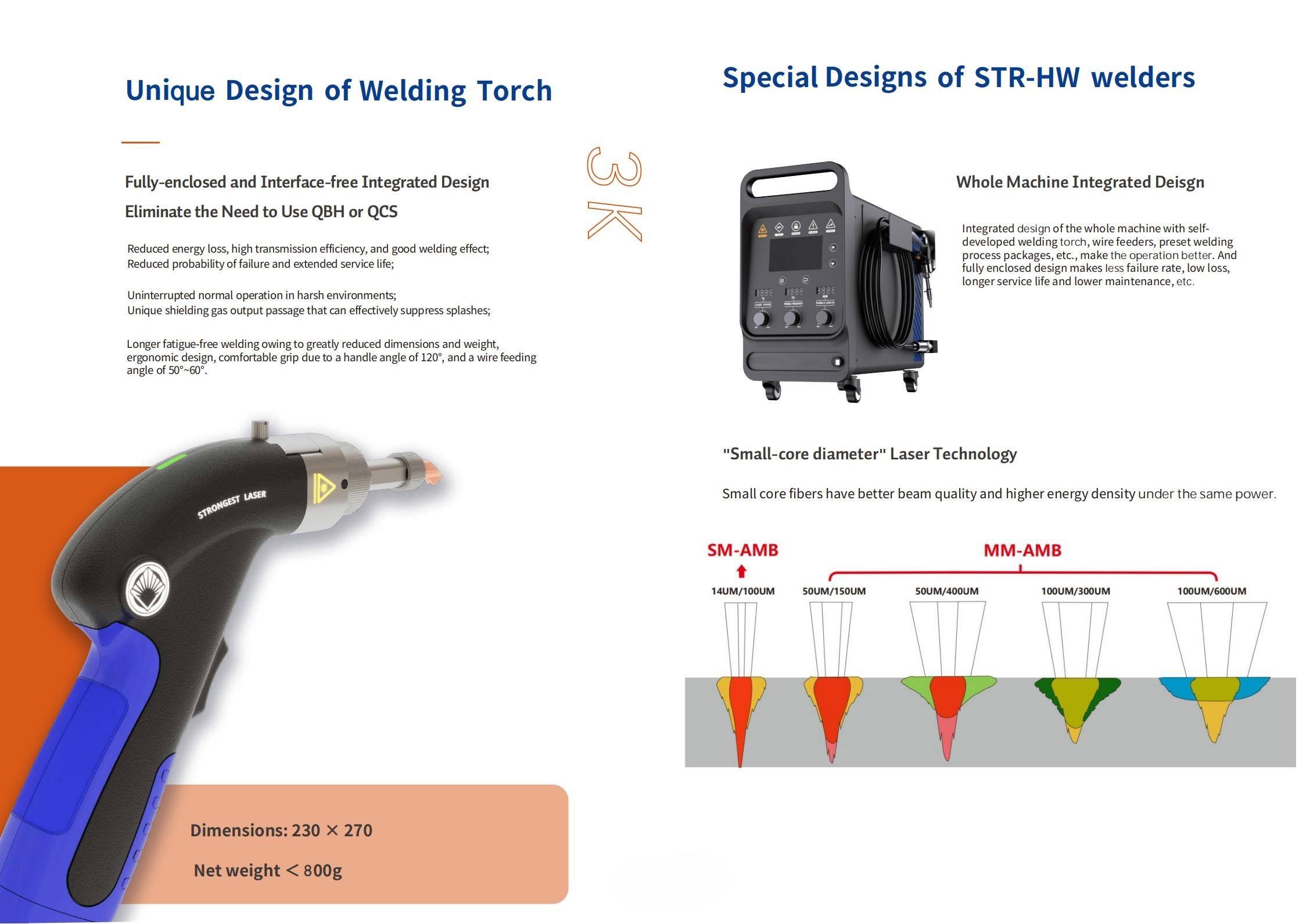

Laser hybrid welding represents a revolutionary advancement in metal joining technology that combines the precision of laser welding with the depth penetration capabilities of arc welding processes. This innovative technique simultaneously employs a focused laser beam and an electric arc to create superior weld joints that exceed the capabilities of either process used independently. The laser hybrid welding system integrates a high-powered laser source, typically fiber or CO2 lasers, with conventional arc welding methods such as Gas Metal Arc Welding (GMAW) or Gas Tungsten Arc Welding (GTAW). The main functions of laser hybrid welding include deep penetration welding for thick materials, precise control over heat input, reduced distortion in finished products, and enhanced welding speeds compared to traditional methods. The technological features that distinguish this process include synchronized operation of both energy sources, adaptive process control systems, real-time monitoring capabilities, and sophisticated beam delivery systems. The laser component provides concentrated energy for precise melting and keyhole formation, while the arc component contributes additional heat input and improved gap bridging capabilities. This dual-energy approach enables manufacturers to achieve exceptional weld quality with minimal post-processing requirements. Applications for laser hybrid welding span numerous industries including automotive manufacturing, shipbuilding, aerospace engineering, pipeline construction, and heavy machinery production. The process proves particularly valuable for joining thick steel plates, aluminum alloys, and dissimilar metals where traditional welding methods struggle to deliver consistent results. Modern laser hybrid welding systems incorporate advanced features such as seam tracking technology, automated parameter adjustment, and comprehensive quality monitoring systems that ensure repeatable results across large production runs.

EN

EN

AR

AR

FR

FR

DE

DE

JA

JA

KO

KO

RU

RU

ES

ES