laser hole drilling

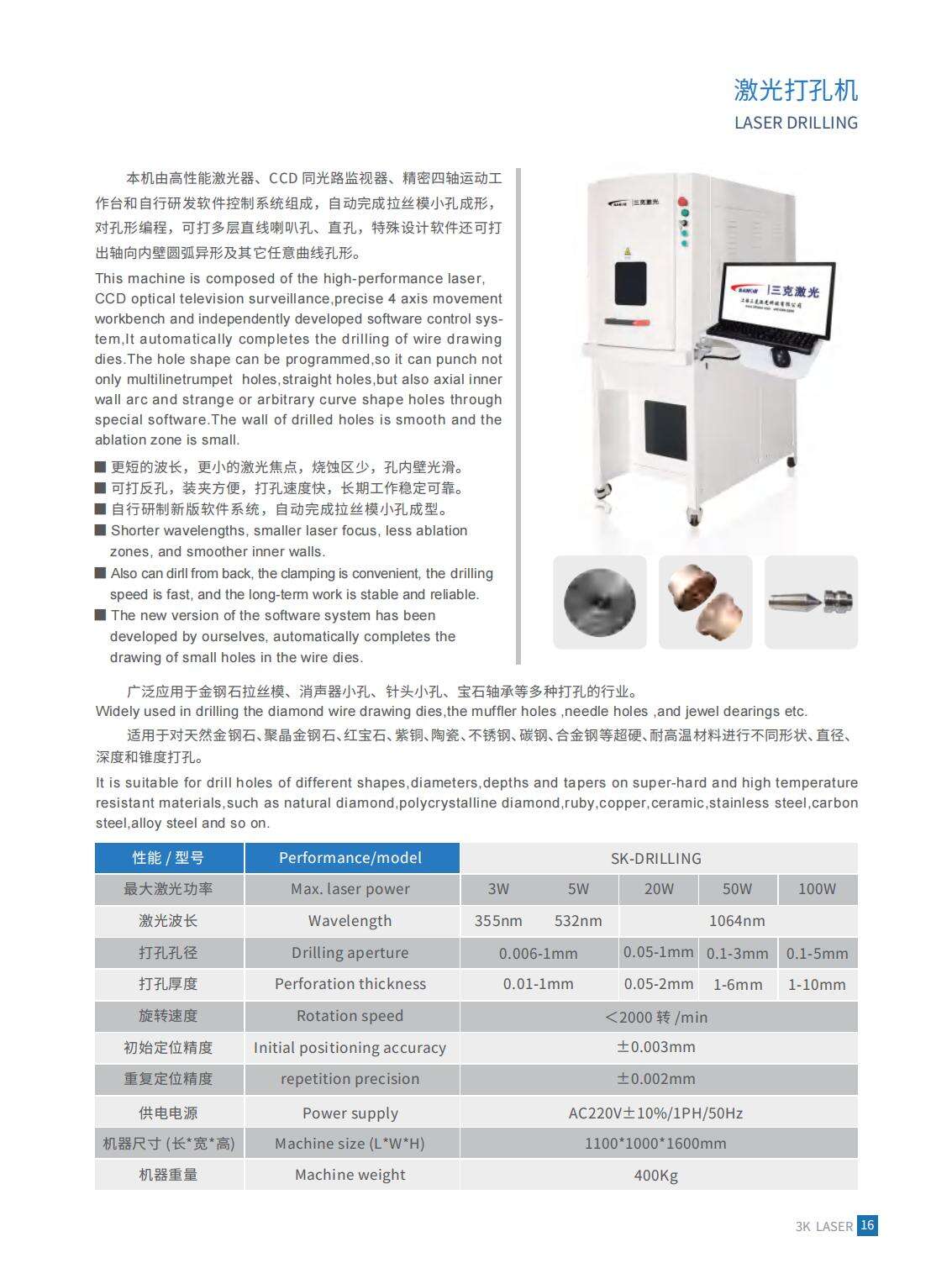

Laser hole drilling represents a revolutionary manufacturing process that utilizes focused laser beams to create precise perforations in various materials with exceptional accuracy and efficiency. This advanced technology employs high-powered laser systems that generate intense concentrated light energy, which vaporizes or melts material at specific targeted locations to form clean, accurate holes. The fundamental principle involves directing a coherent light beam through sophisticated optical systems that focus the energy into extremely small spot sizes, enabling the creation of microscopic to medium-sized apertures with remarkable precision. The main functions of laser hole drilling encompass producing holes with diameters ranging from micrometers to several millimeters, maintaining consistent quality across large production volumes, and achieving complex geometries that traditional mechanical drilling cannot accomplish. Technological features include computer-controlled positioning systems that ensure repeatable accuracy, variable pulse duration capabilities that optimize material processing, and multi-axis movement systems that enable drilling at various angles and orientations. The process offers exceptional flexibility in terms of hole shapes, allowing for round, square, oval, or custom-designed apertures based on specific application requirements. Modern laser hole drilling systems incorporate advanced beam shaping technologies, real-time monitoring capabilities, and sophisticated software controls that optimize processing parameters automatically. These systems can process diverse materials including metals, ceramics, polymers, composites, and semiconductor materials with minimal thermal damage to surrounding areas. Applications span numerous industries including aerospace manufacturing for turbine blade cooling holes, electronics production for circuit board via holes, automotive components requiring precise fluid passages, medical device manufacturing for catheter perforations, and filter production requiring uniform pore distributions. The technology serves critical roles in creating fuel injection nozzles, watch components, jewelry pieces, and specialized industrial components where precision and quality are paramount considerations for successful manufacturing outcomes.

EN

EN

AR

AR

FR

FR

DE

DE

JA

JA

KO

KO

RU

RU

ES

ES