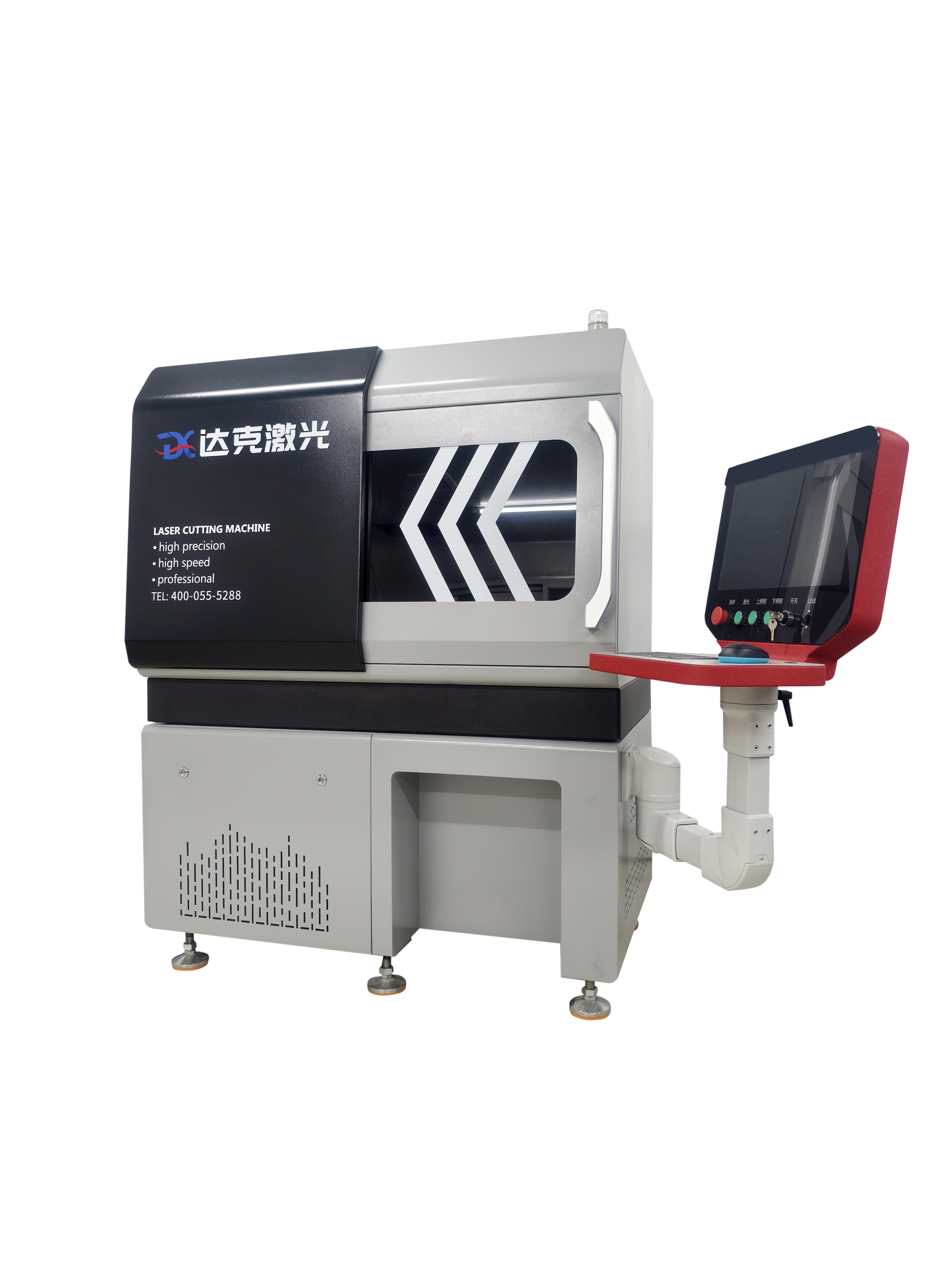

high precision laser drilling process

The high precision laser drilling process represents a cutting-edge manufacturing technology that utilizes focused laser beams to create microscopic holes in various materials with exceptional accuracy and consistency. This advanced technique employs concentrated light energy to vaporize material at precise locations, enabling manufacturers to achieve hole diameters as small as a few micrometers with remarkable dimensional control. The high precision laser drilling process operates through sophisticated beam control systems that can manipulate laser intensity, pulse duration, and positioning with extraordinary precision. The main functions of this technology include creating micro-vias in electronic components, forming cooling holes in turbine blades, producing fuel injection nozzles, and manufacturing medical device components that require exact specifications. Technological features encompass computer-controlled positioning systems, real-time monitoring capabilities, adaptive power control, and multi-axis movement platforms that ensure consistent results across complex geometries. The process can handle various materials including metals, ceramics, polymers, and composite materials, making it versatile for diverse industrial applications. Advanced beam shaping technologies allow operators to optimize hole profiles, minimize heat-affected zones, and achieve superior surface finishes. The high precision laser drilling process finds extensive applications in aerospace manufacturing for creating cooling channels in jet engine components, electronics industry for printed circuit board via formation, automotive sector for fuel system components, medical device production for catheter holes and surgical instruments, and telecommunications for fiber optic connector manufacturing. Quality control systems integrated within the process ensure each drilled hole meets stringent specifications, while automated material handling systems enable high-volume production capabilities that satisfy modern manufacturing demands for both precision and efficiency.

EN

EN

AR

AR

FR

FR

DE

DE

JA

JA

KO

KO

RU

RU

ES

ES