drilling with laser

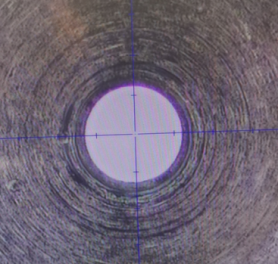

Drilling with laser represents a revolutionary advancement in precision manufacturing and material processing technology. This cutting-edge method utilizes concentrated laser beams to create precise holes, perforations, and micro-channels in various materials with exceptional accuracy and speed. The process involves focusing high-intensity laser energy onto specific points of a workpiece, causing rapid heating and material removal through vaporization or melting. Modern laser drilling systems employ sophisticated beam delivery mechanisms, computer-controlled positioning systems, and real-time monitoring capabilities to ensure consistent results across diverse applications. The technology encompasses multiple laser types, including pulsed and continuous wave systems, each optimized for specific material characteristics and drilling requirements. Advanced beam shaping optics allow operators to control hole geometry, taper angles, and surface finish quality with remarkable precision. Contemporary drilling with laser equipment integrates automated material handling systems, multi-axis positioning platforms, and intelligent process control algorithms to maximize throughput while maintaining strict quality standards. The versatility of this technology enables processing of metals, ceramics, polymers, composites, and semiconductor materials with minimal thermal damage to surrounding areas. Quality control features include real-time depth monitoring, diameter measurement systems, and automated defect detection capabilities. Environmental benefits include reduced waste generation, elimination of chemical processing agents, and lower energy consumption compared to conventional drilling methods. The non-contact nature of drilling with laser eliminates tool wear concerns and reduces maintenance requirements significantly. Integration capabilities with existing manufacturing systems make this technology adaptable to various production environments, from high-volume automotive manufacturing to precision aerospace component production.

EN

EN

AR

AR

FR

FR

DE

DE

JA

JA

KO

KO

RU

RU

ES

ES