high speed laser drilling process

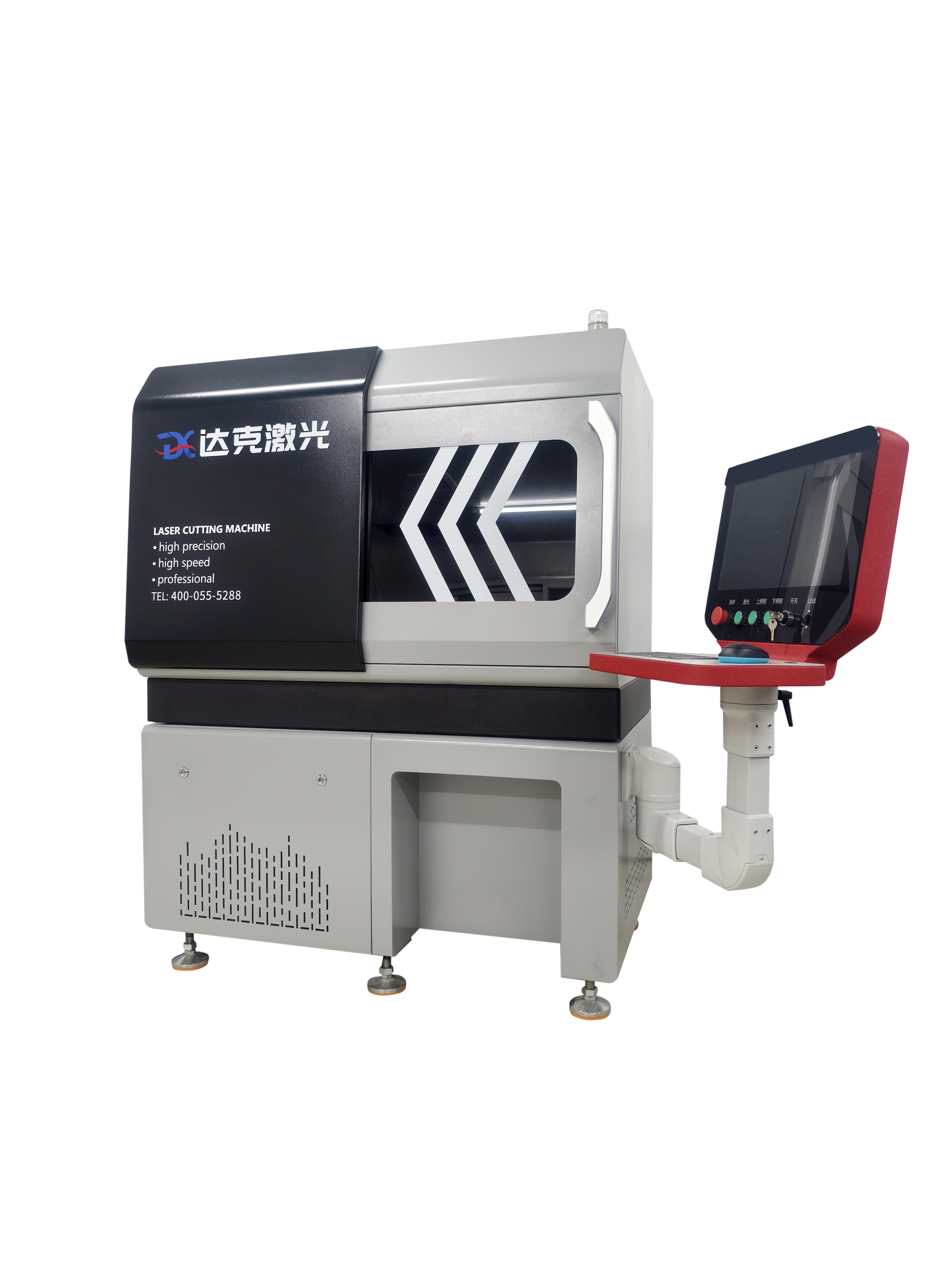

The high speed laser drilling process represents a revolutionary manufacturing technology that utilizes focused laser beams to create precise holes in various materials with exceptional speed and accuracy. This advanced technique employs high-intensity laser pulses that vaporize material instantaneously, forming clean, precise holes without physical contact or mechanical stress. The process operates through thermal ablation, where concentrated photon energy rapidly heats the target material beyond its vaporization point, creating microscopic holes with diameters ranging from micrometers to several millimeters. The high speed laser drilling process functions by directing coherent light through sophisticated optical systems that focus the beam to extremely small spot sizes, achieving power densities exceeding millions of watts per square centimeter. This concentrated energy creates plasma formation that efficiently removes material layer by layer. Key technological features include programmable pulse duration control, variable beam intensity adjustment, precise positioning systems, and real-time monitoring capabilities. The process can operate in multiple modes including continuous wave, pulsed, and burst modes, each optimized for specific material types and hole geometries. Modern systems incorporate advanced beam shaping optics, galvanometer scanning systems, and computer numerical control for automated operation. Applications span numerous industries including aerospace component manufacturing for turbine blade cooling holes, electronics production for printed circuit board via holes, automotive fuel injection nozzle creation, medical device fabrication including stent perforations, and precision engineering components. The high speed laser drilling process proves particularly valuable in semiconductor manufacturing, where it creates through-silicon vias and interconnects. Additional applications include filtration system manufacturing, jewelry production, and research laboratory sample preparation. The technology excels in materials ranging from metals and ceramics to polymers and composites, making it versatile across diverse manufacturing sectors.

EN

EN

AR

AR

FR

FR

DE

DE

JA

JA

KO

KO

RU

RU

ES

ES