laser drilling advantages and disadvantages

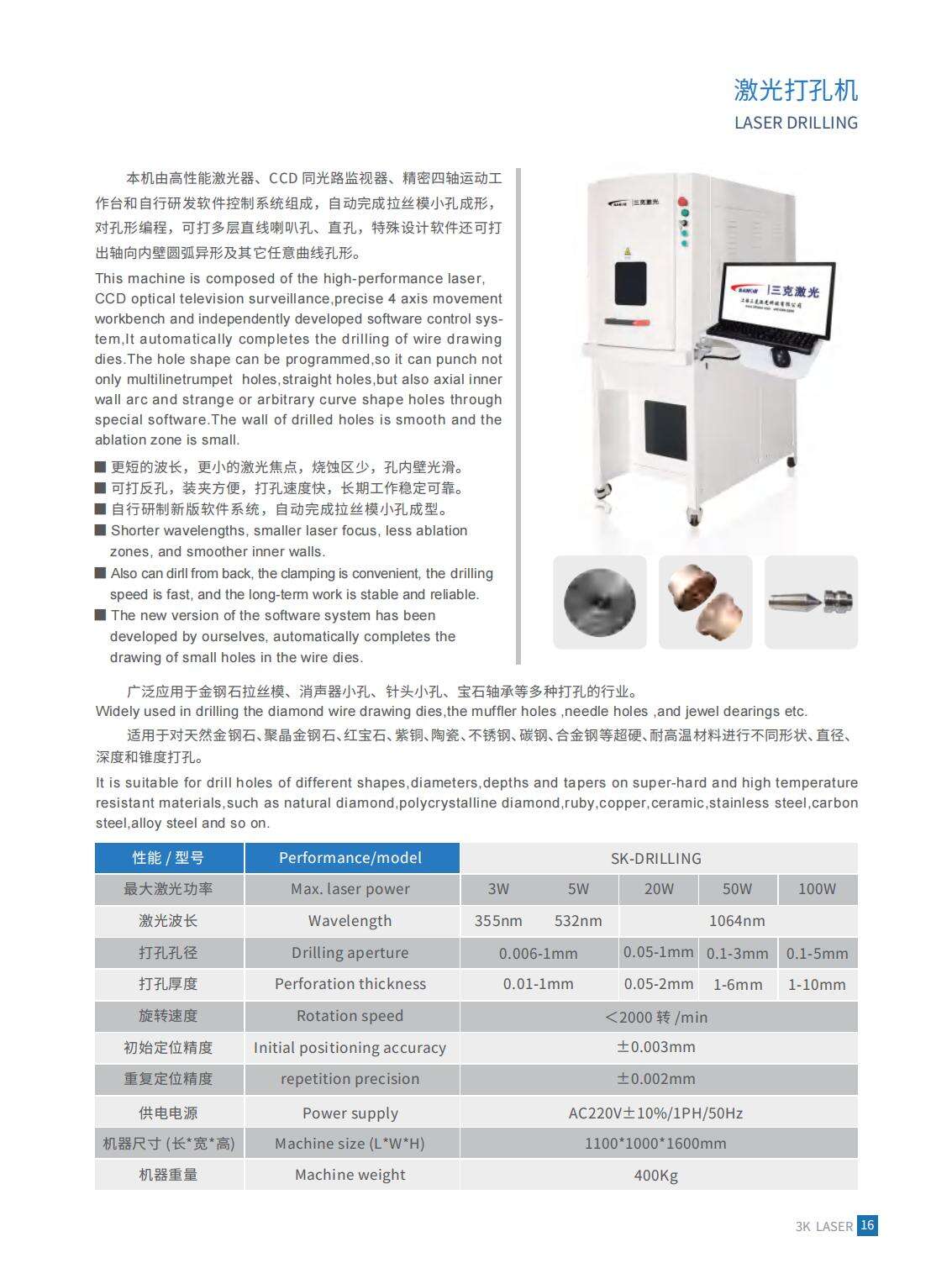

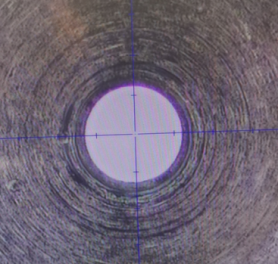

Laser drilling technology represents a revolutionary advancement in precision manufacturing, offering exceptional capabilities for creating precise holes in various materials. This sophisticated process utilizes focused laser beams to remove material through controlled thermal ablation, delivering unmatched accuracy and versatility across multiple industries. Understanding laser drilling advantages and disadvantages is crucial for manufacturers seeking optimal solutions for their specific applications. The technology operates by concentrating intense laser energy onto a small focal point, rapidly heating and vaporizing material to create clean, precise holes. Modern laser drilling systems incorporate advanced beam control mechanisms, real-time monitoring capabilities, and sophisticated software that ensures consistent results. The main functions of laser drilling encompass creating micro-holes, deep drilling applications, trepanning operations, and percussion drilling techniques. Each method serves specific purposes, from creating cooling holes in turbine blades to producing intricate patterns in electronic components. Technological features include pulse duration control, beam shaping capabilities, multi-axis positioning systems, and automated process monitoring. These features enable manufacturers to achieve hole diameters ranging from micrometers to several millimeters with exceptional precision. Applications span aerospace manufacturing, electronics production, automotive components, medical device fabrication, and jewelry creation. In aerospace, laser drilling creates cooling holes in turbine components that enhance engine efficiency. Electronics manufacturers utilize this technology for creating vias in circuit boards and precise openings in semiconductor devices. The automotive industry benefits from laser drilling in fuel injection systems and engine components. Medical device manufacturers rely on this technology for creating precise holes in stents, catheters, and surgical instruments. While laser drilling advantages and disadvantages must be carefully evaluated, the technology continues evolving with improved power efficiency, enhanced beam quality, and reduced operational costs, making it increasingly attractive for diverse manufacturing applications.

EN

EN

AR

AR

FR

FR

DE

DE

JA

JA

KO

KO

RU

RU

ES

ES