Exceptional Material Versatility and Processing Capabilities

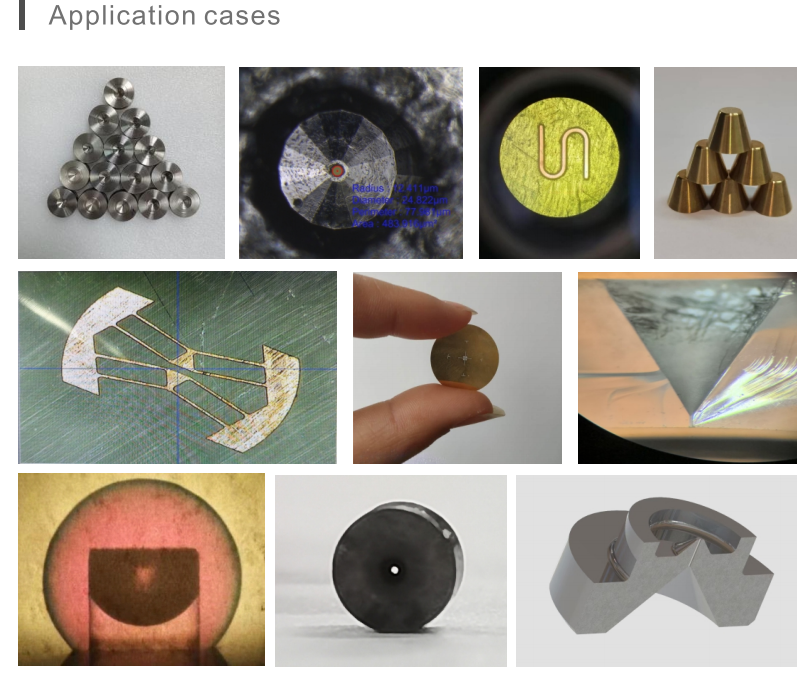

The cnc laser drilling machine demonstrates remarkable versatility in processing an extensive range of materials, making it an invaluable asset for diverse manufacturing environments. This adaptability eliminates the need for multiple specialized drilling systems, significantly reducing capital equipment investments and simplifying production workflows. The laser drilling process effectively handles metals including stainless steel, aluminum, titanium, and exotic alloys commonly used in aerospace and medical applications. Ceramic materials, which pose significant challenges for mechanical drilling due to their brittleness, can be processed cleanly without cracking or chipping. Advanced composite materials, including carbon fiber reinforced plastics and layered structures, benefit from the thermal cutting action that prevents delamination issues common with conventional drilling. The cnc laser drilling machine processes semiconductor materials like silicon and gallium arsenide with exceptional precision, enabling the creation of micro-features essential for electronic device manufacturing. Polymer materials respond well to laser drilling, allowing manufacturers to create precise holes in flexible films, rigid plastics, and multi-layer assemblies. The ability to drill through dissimilar material stacks without tool changes streamlines production processes and reduces setup time between operations. Material thickness capability ranges from ultra-thin films measuring micrometers to thick plates several inches deep, accommodating diverse application requirements within a single system. The laser drilling process adapts automatically to different material properties by adjusting power levels, pulse duration, and repetition rates for optimal results. Heat-sensitive materials benefit from specialized pulsed laser techniques that minimize thermal effects while maintaining hole quality. The non-contact nature prevents material damage from mechanical forces, preserving component integrity throughout the drilling process. Surface treatments and coatings do not interfere with laser drilling performance, unlike mechanical methods that may experience premature tool wear. The system processes materials with varying hardness levels without performance degradation, from soft polymers to hardened tool steels. This versatility enables manufacturers to consolidate multiple drilling operations into a single cnc laser drilling machine, reducing floor space requirements and operational complexity while improving overall manufacturing efficiency.

EN

EN

AR

AR

FR

FR

DE

DE

JA

JA

KO

KO

RU

RU

ES

ES