laser drilling ceramic

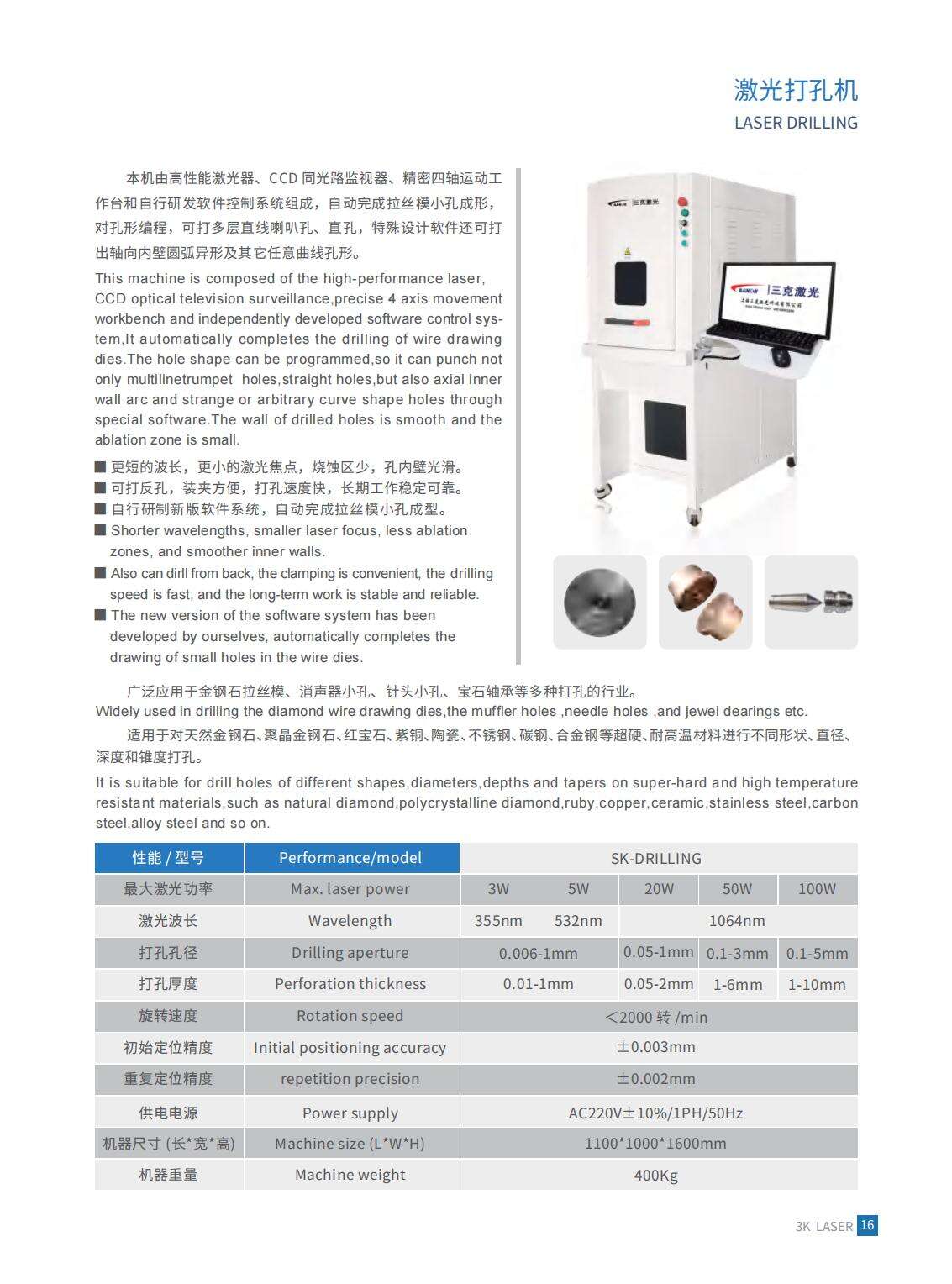

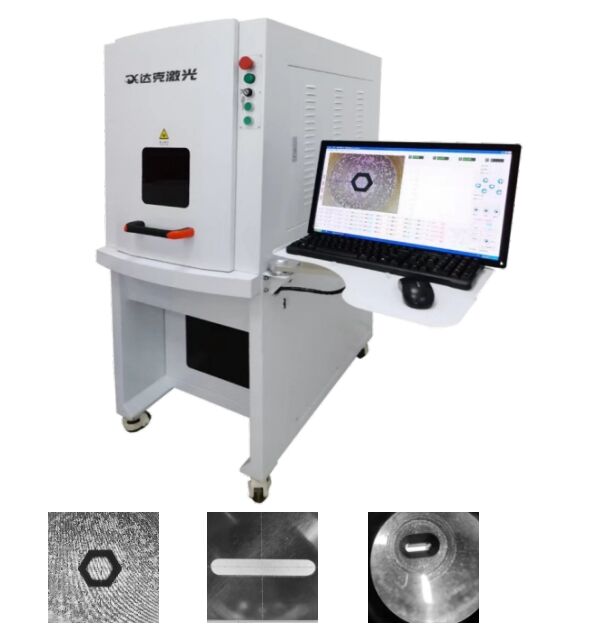

Laser drilling ceramic represents a revolutionary manufacturing process that utilizes focused laser beams to create precise holes and complex patterns in ceramic materials. This advanced technology has transformed how industries approach ceramic processing, offering unparalleled accuracy and efficiency in creating microscopic to large-scale perforations. The laser drilling ceramic process employs high-energy photon beams that selectively remove material through controlled ablation, enabling manufacturers to achieve hole diameters ranging from micrometers to several millimeters with exceptional consistency. The technological foundation of laser drilling ceramic relies on sophisticated beam control systems that precisely manage power density, pulse duration, and focal positioning. These systems integrate advanced optics, computer-controlled positioning mechanisms, and real-time monitoring capabilities to ensure optimal results across diverse ceramic compositions including alumina, zirconia, silicon carbide, and advanced technical ceramics. The process begins with material preparation where ceramic substrates are positioned on precision fixtures, followed by laser parameter optimization based on material properties, desired hole geometry, and depth requirements. Modern laser drilling ceramic systems incorporate multiple wavelength options, allowing operators to select optimal energy absorption characteristics for specific ceramic types. Applications for laser drilling ceramic span numerous industries including aerospace, electronics, automotive, medical devices, and telecommunications. In aerospace applications, laser drilling ceramic creates cooling holes in turbine components and thermal barrier coatings, while electronics manufacturing utilizes this technology for creating vias in ceramic circuit boards and substrates. Medical device manufacturing employs laser drilling ceramic for producing biocompatible implants with precise pore structures that promote tissue integration. The automotive industry leverages this technology for sensor housings and engine components requiring exact dimensional tolerances. Telecommunications benefits from laser drilling ceramic through the production of fiber optic components and high-frequency circuit elements where precision is paramount for signal integrity.

EN

EN

AR

AR

FR

FR

DE

DE

JA

JA

KO

KO

RU

RU

ES

ES