laser dirlling solutions

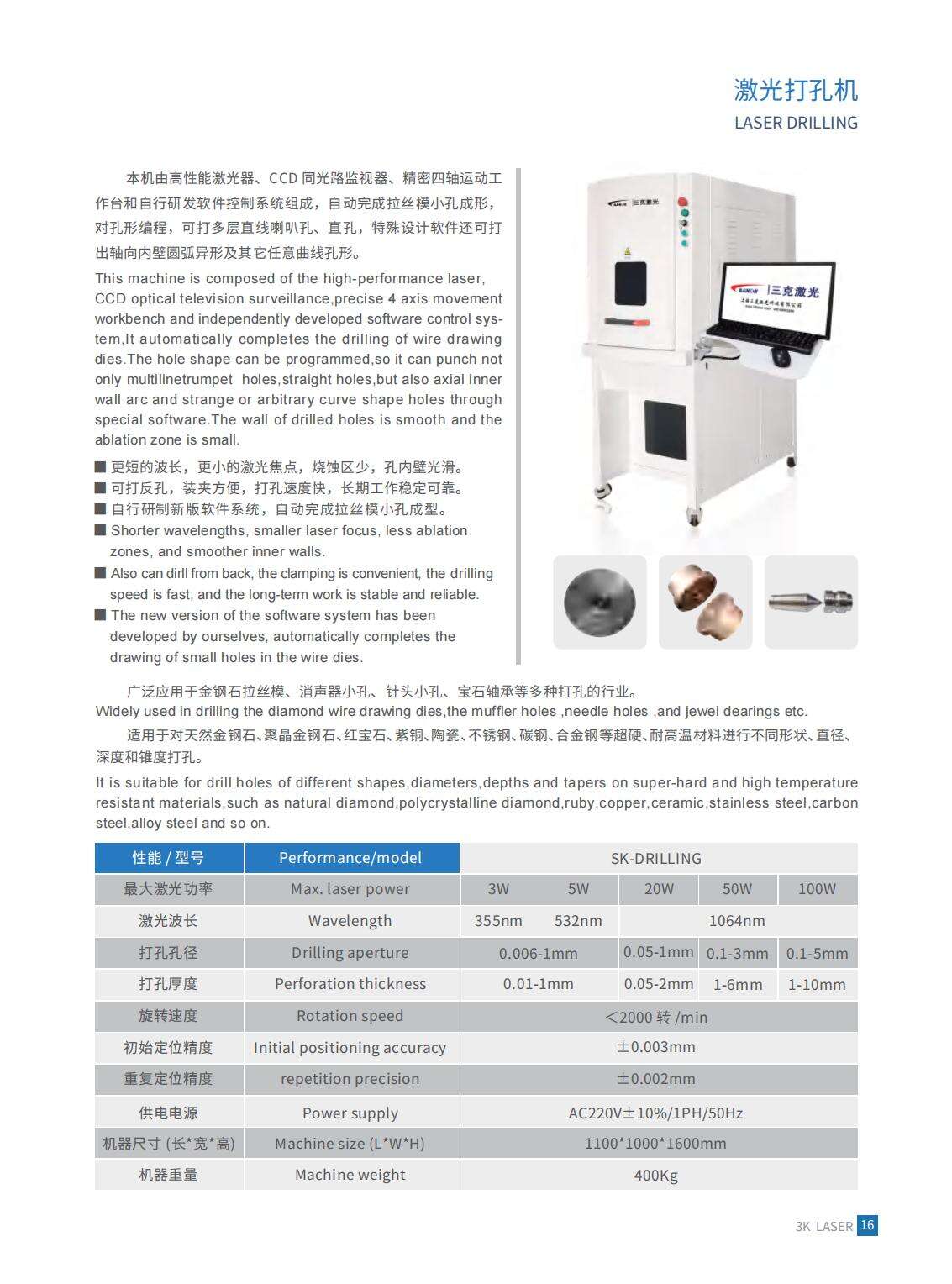

Laser drilling solutions represent cutting-edge manufacturing technology that utilizes focused laser beams to create precise holes in various materials with exceptional accuracy and speed. These advanced systems employ high-powered laser sources, typically fiber, CO2, or ultrafast lasers, to generate intense energy beams that vaporize or melt material along predetermined paths. The main functions of laser drilling solutions encompass micro-drilling for electronics, deep hole drilling for aerospace components, and precision perforation for medical devices. Modern laser drilling systems integrate sophisticated beam delivery mechanisms, computer numerical control systems, and real-time monitoring capabilities to ensure consistent hole quality and dimensional accuracy. The technological features of laser drilling solutions include programmable pulse parameters, adjustable beam focus, multi-axis positioning systems, and automated material handling capabilities. These systems can process diverse materials including metals, ceramics, polymers, composites, and glass with minimal thermal damage to surrounding areas. Advanced laser drilling solutions incorporate adaptive optics for beam shaping, closed-loop feedback systems for process optimization, and intelligent software algorithms that automatically adjust parameters based on material properties and hole specifications. The applications of laser drilling solutions span multiple industries, from creating cooling holes in turbine blades for aerospace engines to manufacturing micro-vias in printed circuit boards for electronics. In the automotive sector, these systems produce fuel injection nozzles and exhaust system components, while medical device manufacturers utilize laser drilling for creating stents, catheters, and surgical instruments. The semiconductor industry relies heavily on laser drilling solutions for wafer processing and package manufacturing, where precision and cleanliness are paramount. Additionally, these systems enable rapid prototyping and small-batch production, making them invaluable for research and development applications across various technological domains.

EN

EN

AR

AR

FR

FR

DE

DE

JA

JA

KO

KO

RU

RU

ES

ES