laser micro-drilling

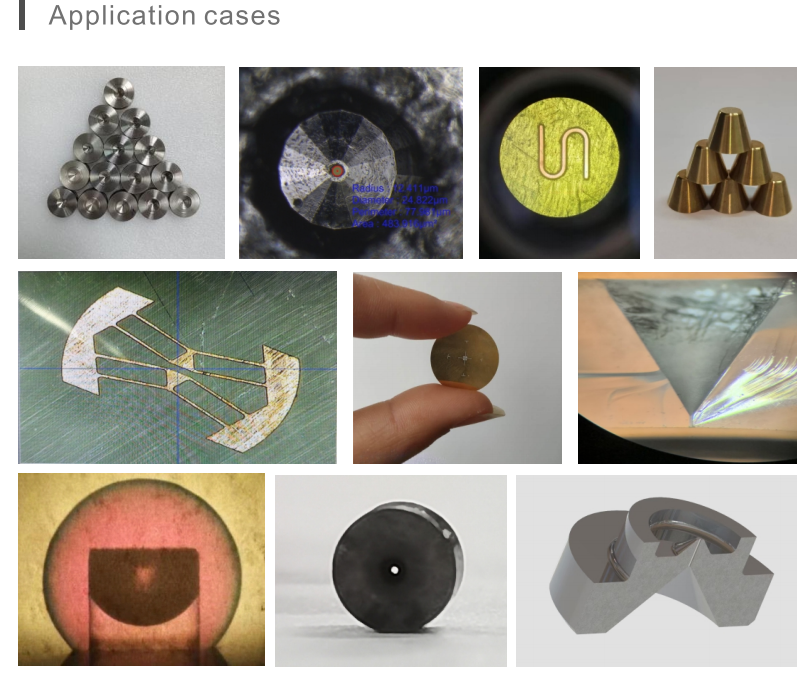

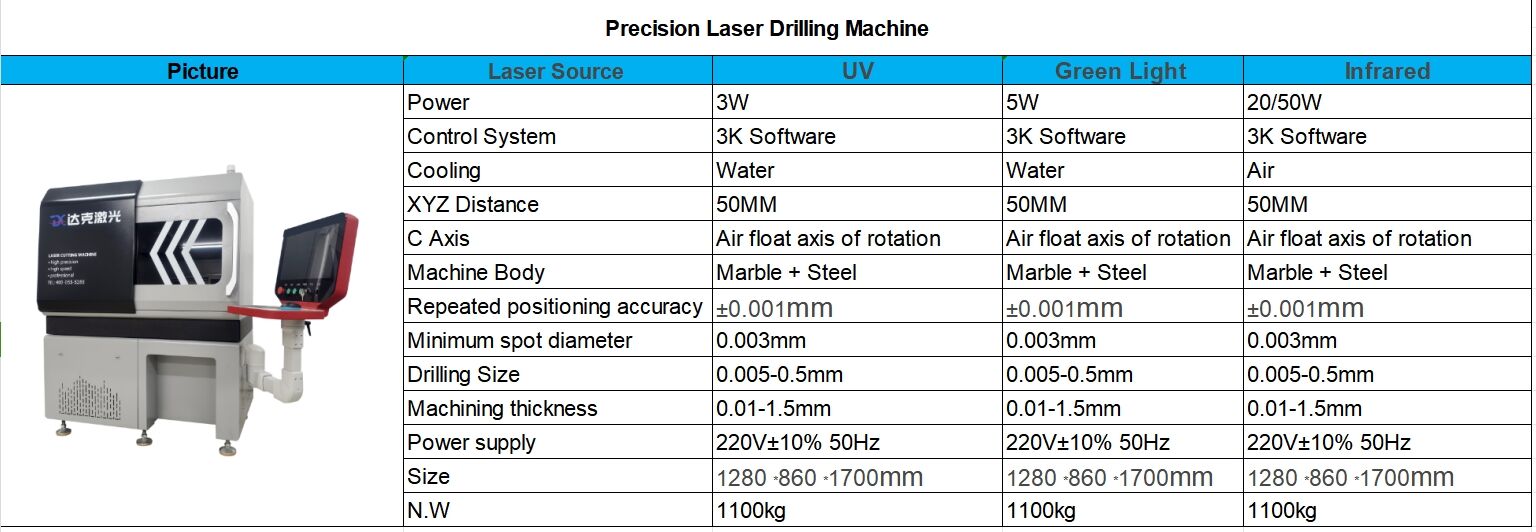

Laser micro-drilling represents a revolutionary manufacturing technology that utilizes focused laser beams to create precise, ultra-small holes in various materials with exceptional accuracy and consistency. This advanced process employs concentrated light energy to vaporize or ablate material, forming microscopic holes ranging from submicron to several hundred microns in diameter. The technology operates on the principle of photon absorption, where intense laser pulses interact with the target material's surface, causing rapid heating and controlled material removal. Modern laser micro-drilling systems incorporate sophisticated beam delivery mechanisms, precision positioning stages, and real-time monitoring capabilities to ensure optimal drilling performance. The main functions of laser micro-drilling include creating precise perforations for filtration applications, forming cooling holes in turbine components, manufacturing medical device apertures, and producing electronic component ventilation systems. Technological features encompass wavelength selection capabilities, pulse duration control, beam shaping options, and automated positioning systems that enable operators to achieve consistent results across large production volumes. The process offers remarkable versatility in handling diverse materials including metals, ceramics, polymers, composites, and semiconductor substrates. Applications span numerous industries, from aerospace and automotive sectors requiring precision cooling holes in engine components, to medical device manufacturing where sterile filtration requires exact pore sizes. Electronics manufacturers utilize laser micro-drilling for creating via holes in printed circuit boards, while textile industries employ the technology for producing breathable fabrics with controlled porosity. The pharmaceutical sector benefits from precise hole formation in drug delivery systems and capsule manufacturing. Research institutions leverage laser micro-drilling for creating microfluidic channels and laboratory-on-chip devices that require exceptional dimensional accuracy and surface quality.

EN

EN

AR

AR

FR

FR

DE

DE

JA

JA

KO

KO

RU

RU

ES

ES