fiber laser welder for sale

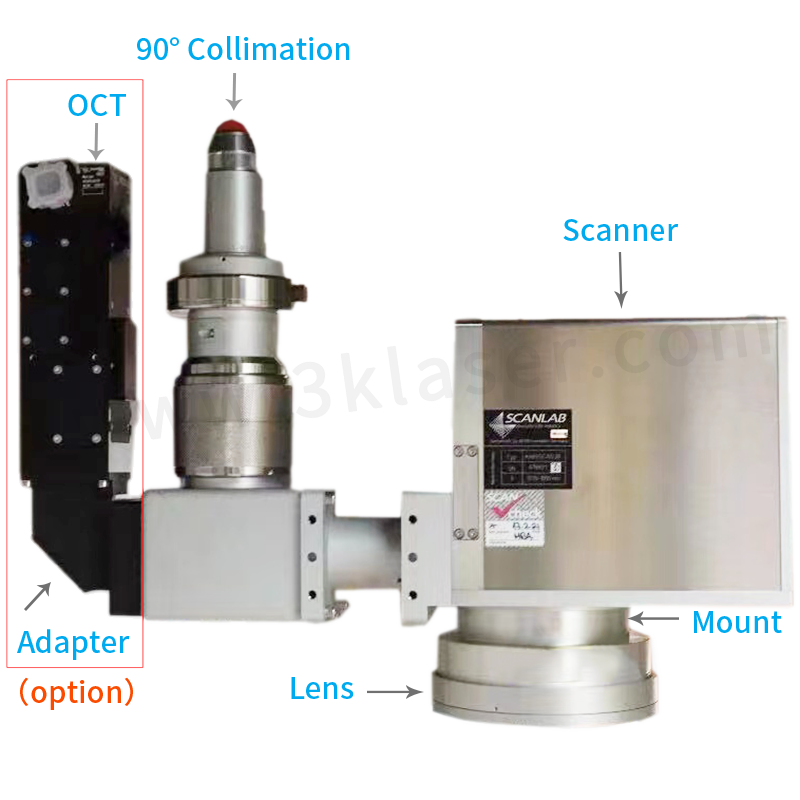

The fiber laser welder for sale represents cutting-edge welding technology that delivers exceptional precision and efficiency for modern manufacturing needs. This advanced welding system utilizes high-powered fiber laser beams to create strong, clean welds across various materials with remarkable accuracy. The main functions of this fiber laser welder for sale include precise metal joining, repair work, and fabrication tasks that demand superior quality results. The system operates through focused laser energy that generates intense heat at specific points, enabling controlled melting and fusion of materials without affecting surrounding areas. Key technological features include adjustable power settings, real-time monitoring systems, and programmable welding parameters that ensure consistent performance. The fiber laser welder for sale incorporates advanced beam delivery systems that maintain stable laser output while providing excellent beam quality throughout extended operations. Its sophisticated control interface allows operators to customize welding profiles for different materials and thicknesses, making it versatile for diverse manufacturing requirements. The system features rapid processing capabilities that significantly reduce production time compared to traditional welding methods. Applications span across automotive manufacturing, aerospace components, medical device production, electronics assembly, and precision tooling industries. The fiber laser welder for sale excels in creating hermetic seals, joining dissimilar metals, and performing micro-welding tasks that require exceptional detail. Its non-contact welding process eliminates tool wear and reduces maintenance requirements while ensuring repeatable results. The technology supports both continuous and pulsed welding modes, accommodating various material types including stainless steel, aluminum, titanium, and specialized alloys. This fiber laser welder for sale delivers consistent weld quality with minimal heat-affected zones, preserving material properties and structural integrity throughout the welding process.

EN

EN

AR

AR

FR

FR

DE

DE

JA

JA

KO

KO

RU

RU

ES

ES