automated pipe welding

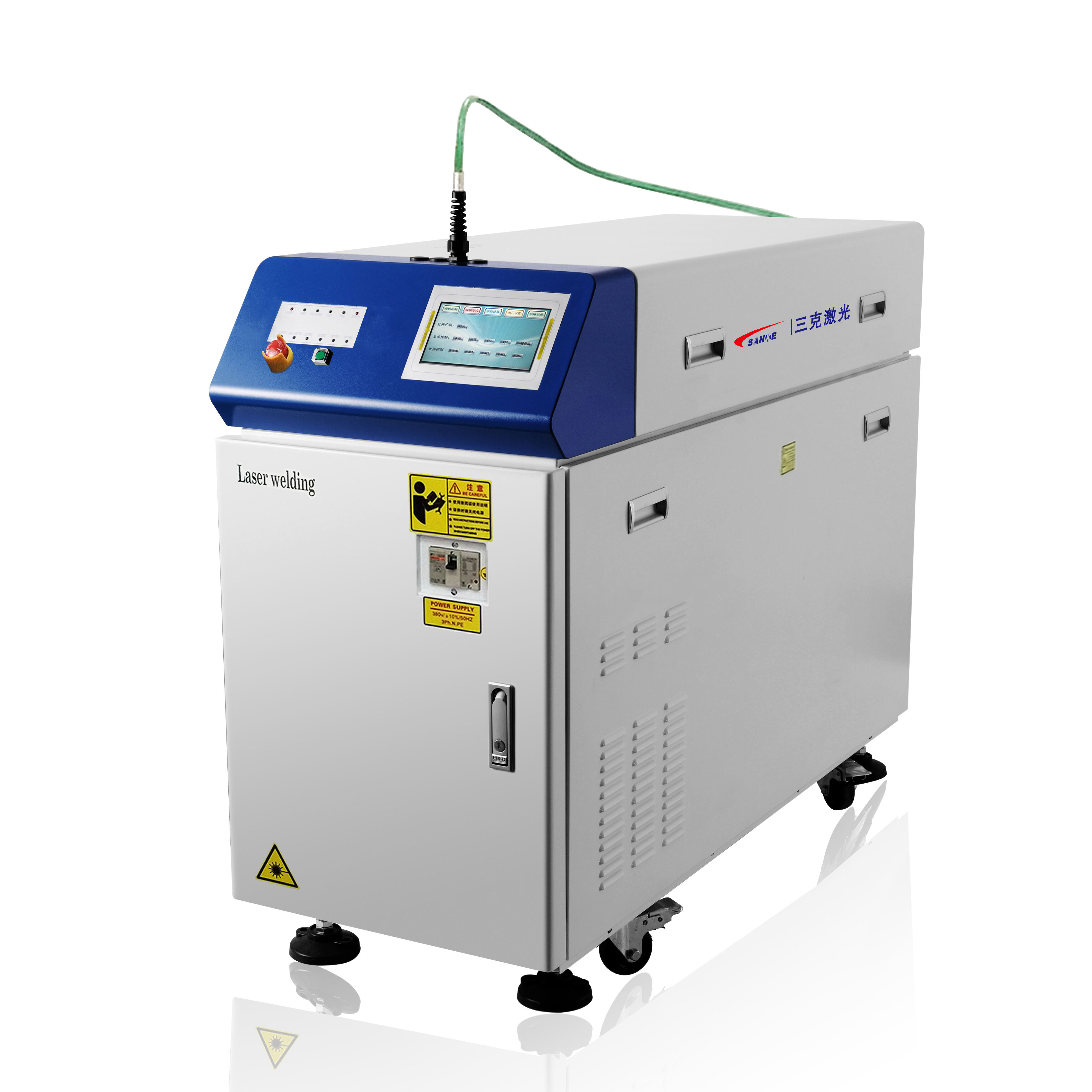

Automated pipe welding represents a revolutionary advancement in industrial manufacturing and construction, transforming how pipelines are joined across various sectors. This sophisticated technology combines precision robotics, advanced sensors, and computerized control systems to deliver consistent, high-quality welds on cylindrical structures. The main functions of automated pipe welding include orbital welding around pipe circumferences, longitudinal seam welding for pipe manufacturing, and multi-pass welding for thick-wall applications. The system operates through programmable parameters that control welding speed, heat input, electrode positioning, and travel patterns, ensuring repeatable results regardless of operator skill levels. Technological features encompass real-time monitoring capabilities that track welding parameters continuously, adaptive control systems that adjust variables based on joint conditions, and integrated quality assurance mechanisms that detect defects during the welding process. Modern automated pipe welding equipment incorporates touch-screen interfaces for easy programming, data logging capabilities for traceability requirements, and remote monitoring options for enhanced safety in hazardous environments. The technology supports various welding processes including Gas Tungsten Arc Welding (GTAW), Gas Metal Arc Welding (GMAW), and Flux-Cored Arc Welding (FCAW), adapting to different material types and thickness requirements. Applications span across oil and gas pipeline construction, power generation facilities, chemical processing plants, pharmaceutical manufacturing, food and beverage production, and aerospace component fabrication. In shipbuilding industries, automated pipe welding ensures watertight seals for critical systems, while in nuclear facilities, it provides the precision required for safety-critical applications. The technology proves invaluable for underwater pipeline installations, where human welders face significant challenges, and in space-constrained environments where consistent access and positioning are difficult to maintain. Manufacturing facilities utilize automated pipe welding for high-volume production runs, achieving throughput rates impossible with manual techniques while maintaining stringent quality standards throughout the process.

EN

EN

AR

AR

FR

FR

DE

DE

JA

JA

KO

KO

RU

RU

ES

ES