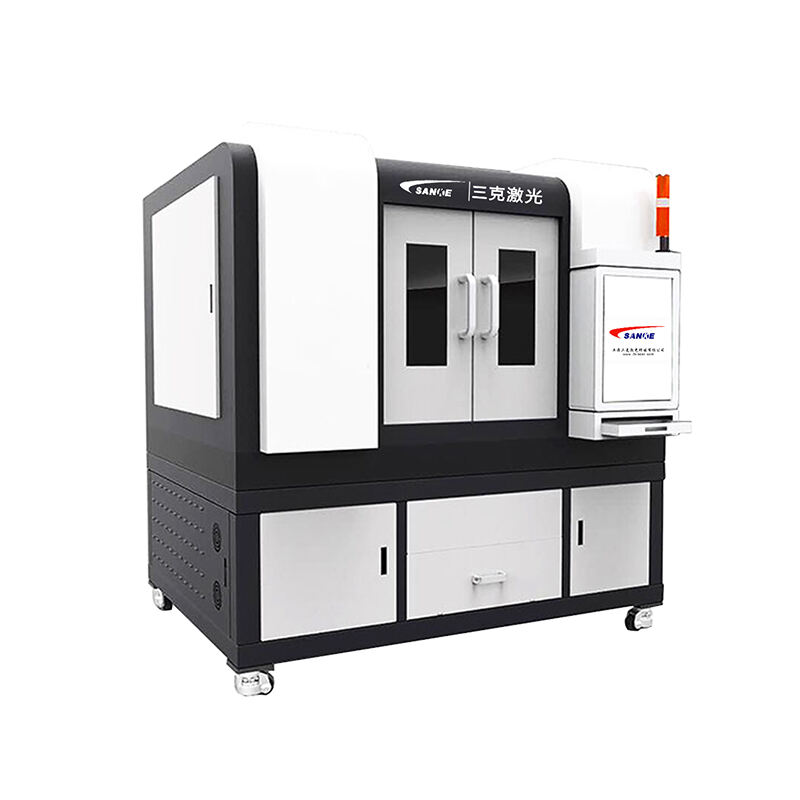

metal laser cutting machine

A metal laser cutting machine represents cutting-edge manufacturing technology that utilizes focused laser beams to precisely cut through various metallic materials. This sophisticated equipment operates by generating an intense beam of coherent light that melts, burns, or vaporizes material along predetermined cutting paths. The metal laser cutting machine incorporates advanced fiber laser technology, delivering exceptional precision and efficiency in metal fabrication processes. These machines feature computer numerical control systems that interpret digital designs and translate them into precise cutting operations. The core functionality revolves around the laser head assembly, which contains focusing lenses and beam delivery components that concentrate laser energy into a narrow focal point. Modern metal laser cutting machines support various metal types including stainless steel, carbon steel, aluminum, brass, copper, and titanium alloys. The cutting process involves multiple technological components working in harmony: the laser generator produces the beam, beam delivery systems transport it to the cutting head, and assist gases help remove molten material from the cut zone. Operating parameters such as laser power, cutting speed, and gas pressure are automatically adjusted based on material thickness and type. These machines excel in producing intricate shapes, complex geometries, and tight tolerances that traditional cutting methods cannot achieve. The metal laser cutting machine integrates seamlessly with computer-aided design software, enabling direct translation from digital blueprints to finished parts. Advanced models feature automatic material handling systems, reducing manual intervention and increasing productivity. Safety features include enclosed cutting areas, fume extraction systems, and protective barriers that shield operators from laser radiation. The technology supports both thin sheet cutting and thick plate processing, making it versatile for diverse manufacturing applications. Quality control systems monitor cutting parameters in real-time, ensuring consistent results across production runs.

EN

EN

AR

AR

FR

FR

DE

DE

JA

JA

KO

KO

RU

RU

ES

ES