Exceptional Material Versatility and Adaptability

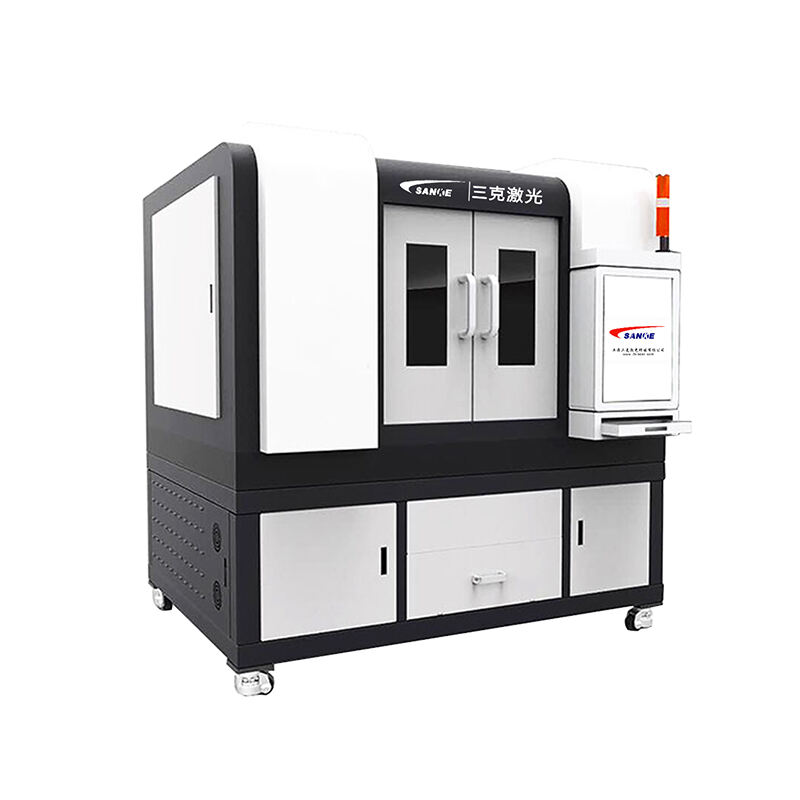

The laser engraving cutting machine demonstrates remarkable adaptability across an extensive range of materials, making it an invaluable asset for diverse manufacturing operations. This versatility stems from the ability to precisely control laser parameters including power output, pulse frequency, cutting speed, and beam focus, allowing optimization for each specific material type and thickness. Organic materials such as wood, leather, fabric, and paper respond excellently to CO2 laser processing, enabling clean cuts and detailed engravings without charring or burning when parameters are properly adjusted. Metal processing capabilities include stainless steel, aluminum, titanium, and various alloys, with fiber laser technology delivering exceptional results on reflective surfaces that challenge other cutting methods. Advanced material handling systems accommodate sheets, tubes, and three-dimensional objects, expanding application possibilities beyond flat panel processing. The laser engraving cutting machine processes synthetic materials including acrylic, polycarbonate, and various engineering plastics with smooth, polished edges that eliminate secondary finishing requirements. Specialized applications include ceramic cutting for electronics, glass engraving for decorative purposes, and composite material processing for aerospace applications. Material thickness capabilities range from delicate films measured in micrometers to substantial plates several centimeters thick, depending on laser power specifications and material properties. The non-contact processing approach eliminates concerns about material deformation or surface damage caused by mechanical clamping or tool pressure. This adaptability enables manufacturers to consolidate multiple processes into a single machine, reducing equipment investment and floor space requirements while increasing operational flexibility.

EN

EN

AR

AR

FR

FR

DE

DE

JA

JA

KO

KO

RU

RU

ES

ES