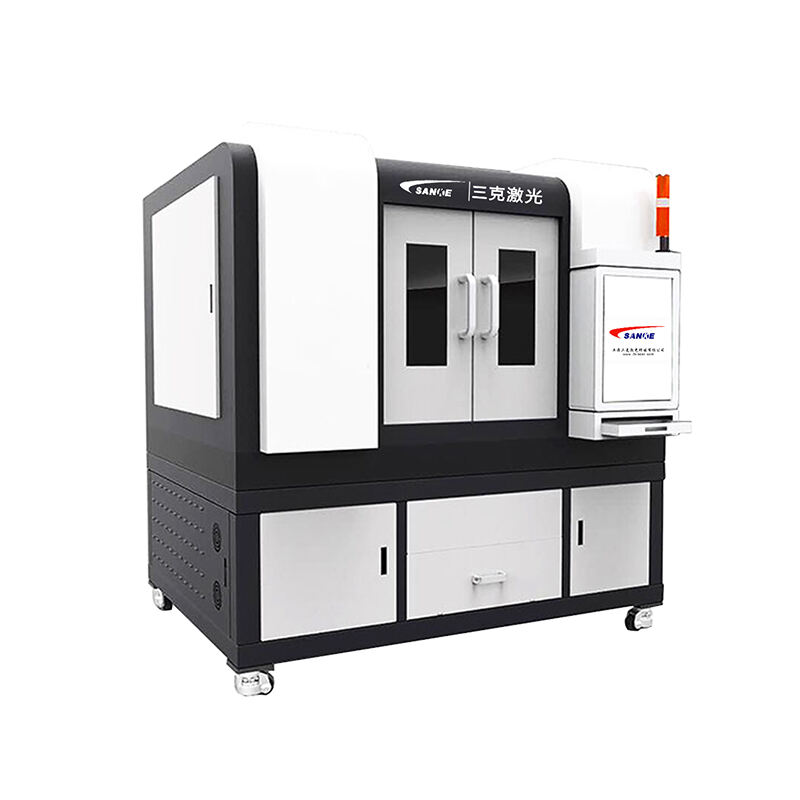

engraving laser cutting machine

The engraving laser cutting machine represents a revolutionary advancement in precision manufacturing technology, combining the capabilities of detailed engraving with accurate cutting operations in a single versatile system. This sophisticated equipment utilizes high-powered laser beams to create intricate designs, patterns, and cuts across various materials with exceptional accuracy and speed. Modern engraving laser cutting machines incorporate advanced control systems that enable operators to achieve precise results while maintaining consistent quality throughout production runs. The technology operates by focusing an intense laser beam onto the material surface, which generates sufficient heat to either vaporize material for cutting or modify surface characteristics for engraving purposes. These machines support multiple material types including metals, plastics, wood, leather, glass, ceramics, and composite materials, making them indispensable tools across numerous industries. The main functions of an engraving laser cutting machine encompass vector cutting, raster engraving, surface marking, and material processing at microscopic levels. Vector cutting allows for clean separation of materials along predetermined paths, while raster engraving creates detailed images and text by selectively removing or modifying surface layers. Technological features include computer numerical control systems, automatic focusing mechanisms, real-time monitoring capabilities, and integrated cooling systems that ensure optimal performance. Advanced models incorporate rotary attachments for cylindrical objects, multiple laser head configurations, and sophisticated software packages that streamline design-to-production workflows. The precision capabilities of these machines enable tolerances measured in hundredths of millimeters, making them suitable for applications requiring extreme accuracy. Industrial applications span automotive component manufacturing, aerospace part production, medical device creation, jewelry fabrication, signage production, architectural model making, and custom prototyping services. Educational institutions utilize these machines for research projects and student training programs, while small businesses leverage their capabilities for custom product development and personalized manufacturing services.

EN

EN

AR

AR

FR

FR

DE

DE

JA

JA

KO

KO

RU

RU

ES

ES