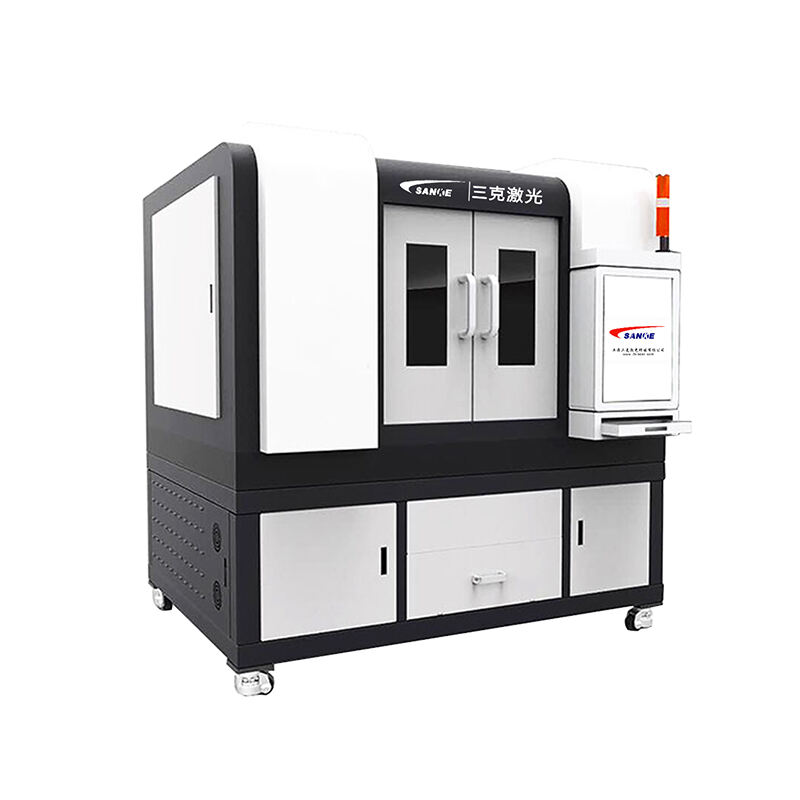

Laser cutting integration solution supplier

A laser cutting integration solution supplier represents a specialized technology partner that delivers comprehensive manufacturing systems combining advanced laser cutting capabilities with integrated automation, software, and support services. These suppliers focus on providing end-to-end solutions that transform raw materials into precision-cut components through sophisticated laser technology platforms. The main functions of a laser cutting integration solution supplier encompass system design, equipment installation, process optimization, and ongoing technical support to ensure maximum operational efficiency. These providers typically offer multi-faceted laser cutting systems that incorporate fiber lasers, CO2 lasers, and hybrid technologies capable of processing diverse materials including metals, plastics, ceramics, and composites. The technological features of modern laser cutting integration solutions include real-time monitoring systems, automated material handling mechanisms, intelligent nesting software, and predictive maintenance capabilities that minimize downtime while maximizing throughput. Advanced beam delivery systems ensure consistent cut quality across varying material thicknesses, while integrated CAD/CAM software streamlines the transition from design concept to finished product. Applications for laser cutting integration solution supplier services span numerous industries including automotive manufacturing, aerospace component production, electronics fabrication, architectural metalwork, and medical device manufacturing. These solutions enable precision cutting of intricate geometries, complex patterns, and tight tolerances that traditional cutting methods cannot achieve. The integration aspect encompasses seamless connectivity between laser cutting equipment and existing production lines, inventory management systems, and quality control protocols. Modern laser cutting integration solution suppliers also provide cloud-based monitoring platforms that enable remote diagnostics, performance analytics, and predictive maintenance scheduling to optimize operational efficiency and reduce unexpected equipment failures.

EN

EN

AR

AR

FR

FR

DE

DE

JA

JA

KO

KO

RU

RU

ES

ES