Unmatched Versatility and Material Compatibility

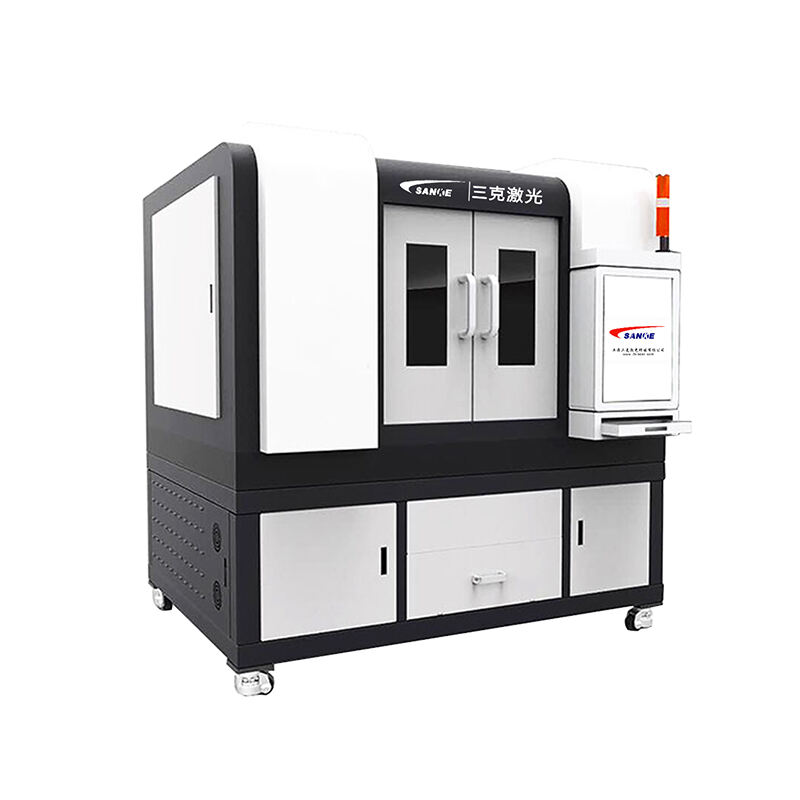

The laser cutting machine for metal demonstrates extraordinary versatility by processing an extensive range of metallic materials with varying thicknesses, compositions, and properties within a single, unified system. This comprehensive material compatibility eliminates the need for multiple specialized cutting machines, reducing capital investments, facility space requirements, and operator training needs significantly. A single laser cutting machine for metal can efficiently process stainless steel, carbon steel, aluminum, copper, brass, titanium, and numerous exotic alloys, adapting cutting parameters automatically to optimize performance for each specific material. The thickness capabilities range from ultra-thin foils measuring mere micrometers to substantial plates several inches thick, providing manufacturers with complete flexibility across their product portfolios. The laser cutting machine for metal excels at handling reflective materials like aluminum and copper that pose challenges for other cutting technologies, utilizing advanced beam delivery systems and wavelength optimization to achieve consistent results. The versatility extends beyond basic cutting operations to include engraving, marking, perforating, and texturing capabilities that add value to finished products without requiring additional equipment or processing steps. Different laser types integrated into modern laser cutting machines for metal, including fiber, CO2, and crystal lasers, optimize performance across various material categories and thickness ranges. The system's ability to process both ferrous and non-ferrous metals within the same production run streamlines manufacturing workflows and reduces setup times between different jobs. Advanced laser cutting machines for metal incorporate intelligent material recognition systems that automatically adjust power, speed, and gas settings based on the detected material type and thickness. The flexibility to cut both sheet materials and structural shapes expands application possibilities, enabling manufacturers to serve diverse market segments with a single equipment investment. The quick changeover capabilities of laser cutting machines for metal allow rapid transitions between different materials, thicknesses, and cutting requirements without lengthy setup procedures or specialized tooling changes. This versatility proves particularly valuable for job shops, custom manufacturers, and companies serving multiple industries with varying material requirements and specifications.

EN

EN

AR

AR

FR

FR

DE

DE

JA

JA

KO

KO

RU

RU

ES

ES