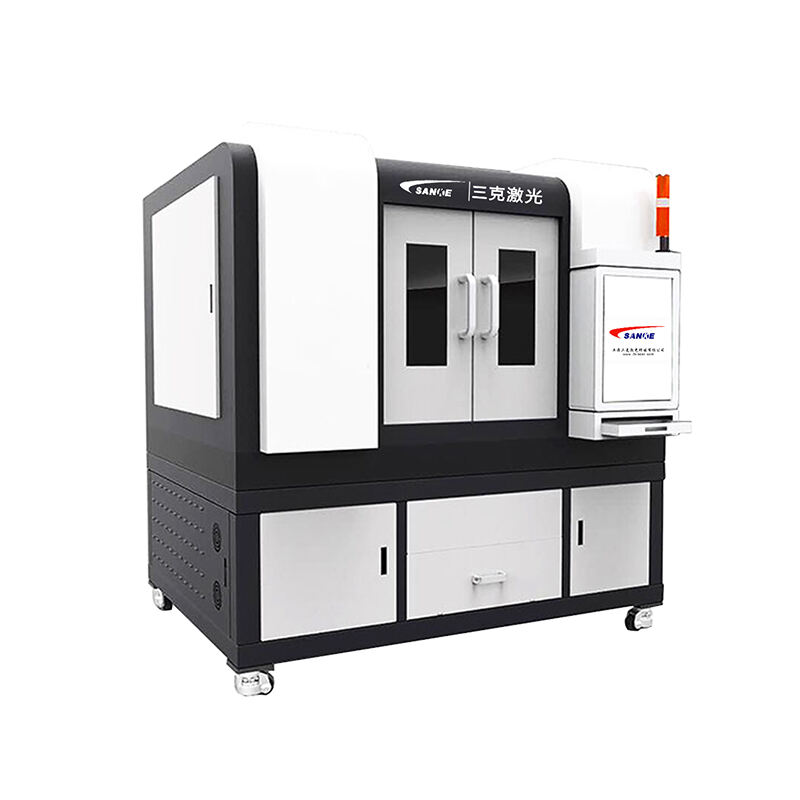

Exceptional Material Versatility and Adaptability

The CO2 laser cutting machine demonstrates remarkable versatility by processing an extensive array of materials with varying properties, thicknesses, and characteristics, making it an invaluable asset for diverse manufacturing applications. This adaptability stems from the 10.6-micrometer wavelength that interacts effectively with organic and many inorganic materials, providing manufacturers with unprecedented flexibility in material selection and product design. Metals including stainless steel, carbon steel, aluminum, titanium, and brass can be cut with thicknesses ranging from thin foils to plates exceeding 25 millimeters, depending on laser power and material properties. Non-metallic materials such as acrylic, polycarbonate, polyethylene, wood, paper, cardboard, fabric, leather, and ceramics process efficiently with excellent edge quality and minimal thermal damage. The machine's parameter adjustment capabilities allow operators to optimize cutting speed, power levels, and assist gas selection for each specific material combination, ensuring optimal results across different substrates. This versatility eliminates the need for multiple specialized cutting systems, reducing equipment investment and facility space requirements while streamlining production workflows. Manufacturers can quickly switch between different materials and thicknesses without lengthy setup procedures or tool changes, enabling efficient small-batch production and rapid prototyping services. The ability to process both thick structural materials and delicate thin films within the same system provides exceptional value for job shops and custom manufacturers serving diverse client requirements. Material compatibility extends to composite materials, layered substrates, and specialty alloys commonly used in advanced applications. The consistent cutting quality across different materials ensures predictable results and reduces the learning curve for new material introductions. This versatility advantage enables businesses to expand their service offerings, enter new markets, and respond quickly to changing customer demands without additional capital equipment investments.

EN

EN

AR

AR

FR

FR

DE

DE

JA

JA

KO

KO

RU

RU

ES

ES