The manufacturing and personalization industries are experiencing a revolutionary shift as holographic engraving technology challenges traditional engraving methods. This cutting-edge approach combines three-dimensional visual effects with precision marking capabilities, creating stunning results that were previously impossible to achieve. As businesses seek more innovative ways to brand their products and create memorable customer experiences, the debate between holographic engraving and conventional techniques has intensified across multiple sectors.

Traditional engraving methods have served industries well for decades, providing reliable marking solutions for identification, branding, and decorative purposes. However, the emergence of holographic engraving technology has introduced possibilities that extend far beyond simple surface modifications. This advanced technique creates multi-dimensional visual effects that change appearance based on viewing angle, lighting conditions, and observer position, offering unprecedented opportunities for product differentiation and brand recognition.

Understanding Holographic Engraving Technology

The Science Behind Holographic Effects

Holographic engraving operates on principles of light interference and diffraction, creating patterns that manipulate how light interacts with engraved surfaces. Unlike traditional methods that simply remove or modify surface material, holographic engraving creates microscopic structures that bend and scatter light in specific ways. These precisely controlled patterns generate three-dimensional visual effects that appear to float above or below the actual surface, creating an illusion of depth and movement.

The technology utilizes sophisticated laser systems capable of creating interference patterns with nanometer-level precision. When light strikes these patterns, it creates constructive and destructive interference, producing the characteristic rainbow-like colors and shifting visual effects associated with holograms. This process requires extremely stable laser systems and precise control mechanisms to ensure consistent results across production runs.

Equipment and Process Requirements

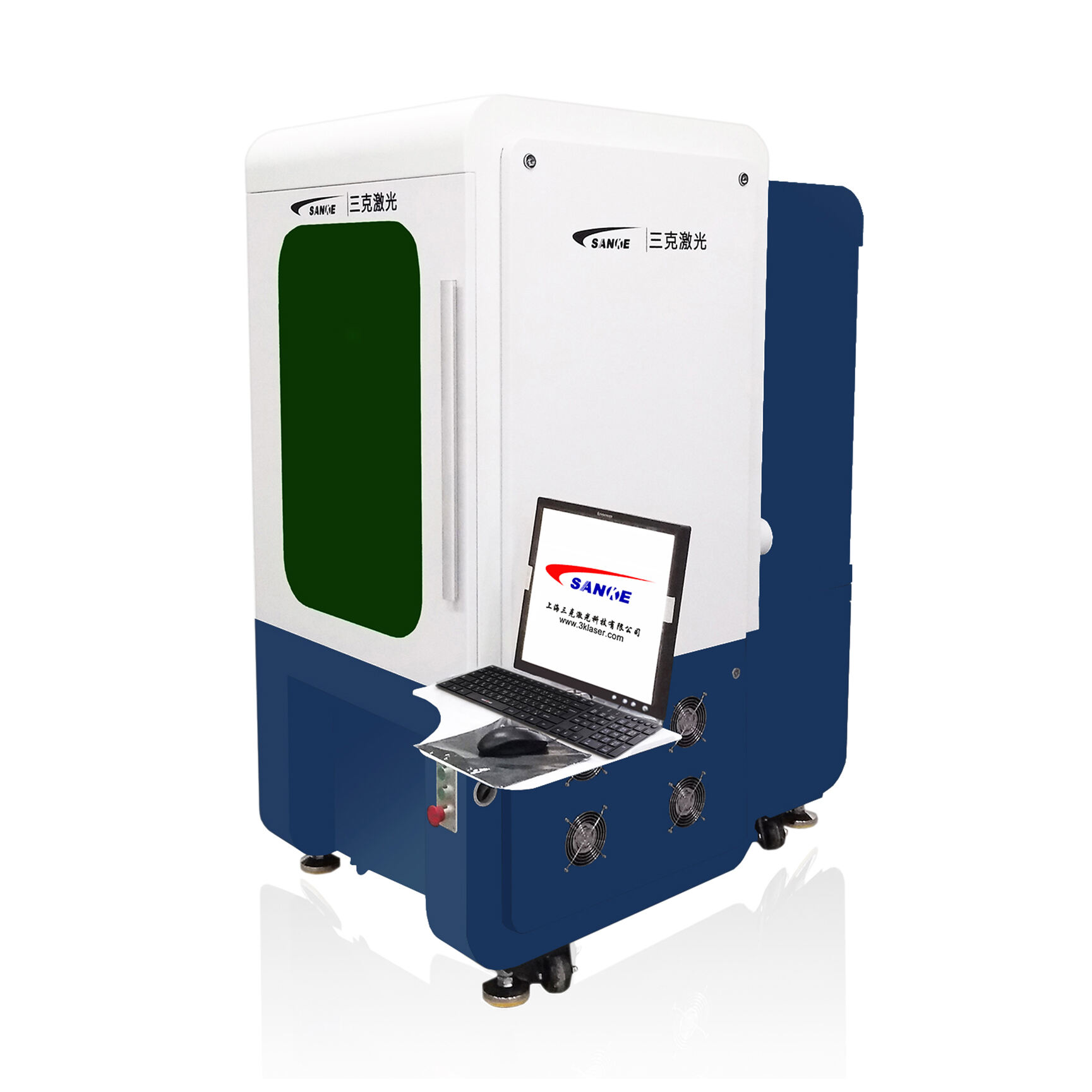

Modern holographic engraving systems incorporate advanced laser technology, typically using coherent light sources such as diode pumped solid-state lasers or fiber lasers. These systems must maintain exceptional beam quality and stability to create the interference patterns necessary for holographic effects. The equipment also includes sophisticated motion control systems that can position the laser beam with sub-micron accuracy.

The engraving process itself involves creating multiple overlapping interference patterns, each contributing to the final holographic effect. Computer-controlled systems calculate the precise positioning and intensity requirements for each laser pulse, ensuring that the cumulative effect produces the desired visual result. This level of control requires significant computational power and specialized software designed specifically for holographic pattern generation.

Traditional Engraving Methods Overview

Mechanical Engraving Techniques

Traditional mechanical engraving relies on physical cutting tools to remove material from the workpiece surface, creating permanent marks through controlled material removal. Rotary engravers, diamond drag systems, and CNC milling machines represent the most common mechanical approaches, each offering specific advantages for different applications. These methods have proven reliable across countless industries, from jewelry manufacturing to industrial part marking.

The mechanical approach provides excellent durability and readability, particularly for applications requiring deep engraving or raised letter effects. Tool selection, cutting speeds, and feed rates can be adjusted to accommodate various materials, from soft plastics to hardened steels. However, mechanical methods are limited in terms of the complexity of patterns they can create and typically require more time per part compared to laser-based alternatives.

Laser Engraving Fundamentals

Traditional laser engraving uses focused thermal energy to vaporize, melt, or chemically alter surface material, creating permanent marks without physical contact between the laser and workpiece. CO2 lasers, fiber lasers, and UV lasers each offer specific advantages for different materials and applications. This non-contact process eliminates tool wear and allows for intricate pattern creation that would be impossible with mechanical methods.

Laser systems provide exceptional precision and repeatability, making them ideal for high-volume production environments where consistency is critical. The ability to quickly change engraving patterns through software updates rather than physical tool changes significantly reduces setup times and increases flexibility. However, traditional laser engraving produces primarily two-dimensional results, lacking the visual depth and dynamic effects possible with holographic techniques.

Performance Comparison Analysis

Visual Impact and Aesthetic Appeal

The most significant difference between holographic engraving and traditional methods lies in visual impact and aesthetic appeal. Holographic engraving creates dynamic, three-dimensional effects that capture attention and create memorable impressions. The shifting colors and apparent depth changes as viewing angles change provide a level of visual interest impossible to achieve with conventional engraving techniques.

Traditional engraving methods, while limited to static appearances, offer their own aesthetic advantages. The crisp, clean lines and consistent depth of mechanical engraving create a professional, timeless appearance that many customers prefer. The permanence and readability of traditional methods make them particularly suitable for applications where function takes precedence over visual flair, such as industrial part identification or legal markings.

Durability and Longevity Factors

Durability comparisons between holographic engraving and traditional methods reveal important considerations for different applications. Traditional mechanical and laser engraving typically create more robust marks that can withstand harsh environmental conditions, abrasive contact, and chemical exposure. The physical depth of mechanically engraved marks provides excellent resistance to wear and ensures long-term readability.

Holographic engraving durability depends heavily on the substrate material and environmental conditions. While the microscopic structures created during holographic engraving are permanent, they may be more susceptible to damage from abrasive contact or chemical exposure. However, recent advances in protective coatings and substrate preparation techniques have significantly improved the durability of holographic engraving applications, making them suitable for many demanding environments.

Cost Analysis and Economic Considerations

Initial Equipment Investment

The financial investment required for holographic engraving equipment significantly exceeds that of traditional engraving systems. Advanced laser systems capable of creating holographic effects typically cost several times more than conventional laser engravers or mechanical systems. This higher initial investment must be justified through increased revenue opportunities, premium pricing capabilities, or unique market positioning advantages.

Traditional engraving equipment offers more affordable entry points, with basic mechanical systems available at relatively modest costs. Even high-end CNC engravers and industrial laser systems typically require lower initial investments compared to holographic engraving technology. This cost advantage makes traditional methods more accessible for small businesses or those just entering the engraving market.

Operating Costs and Maintenance Requirements

Operating costs for holographic engraving systems tend to be higher due to the precision requirements and complexity of the equipment. Specialized maintenance, calibration procedures, and potential component replacements contribute to ongoing expenses. The need for highly skilled operators familiar with holographic principles and equipment operation may also increase labor costs.

Traditional engraving methods generally offer lower operating costs, particularly for mechanical systems with replaceable cutting tools. Maintenance procedures are typically more straightforward, and operator training requirements are less intensive. However, tool replacement costs and the potential for material waste during setup and testing can contribute to overall operating expenses.

Application Suitability and Market Segments

Industrial and Manufacturing Applications

Industrial applications often prioritize functionality, durability, and cost-effectiveness over visual appeal, making traditional engraving methods more suitable for many manufacturing environments. Part identification, serial numbering, compliance marking, and traceability requirements typically favor proven traditional techniques that provide reliable, readable marks under harsh conditions.

However, holographic engraving is finding increasing acceptance in industries where brand differentiation and anti-counterfeiting measures are important. Automotive components, electronics manufacturing, and aerospace applications are beginning to incorporate holographic engraving for both functional and security purposes. The unique visual characteristics make unauthorized reproduction extremely difficult, providing valuable brand protection benefits.

Consumer Products and Luxury Markets

Consumer products and luxury markets represent ideal applications for holographic engraving technology, where visual impact and perceived value often justify premium pricing. Jewelry, watches, consumer electronics, and promotional products can benefit significantly from the distinctive appearance and perceived technological sophistication of holographic engraving.

Traditional engraving maintains strong positions in markets where classic aesthetics and proven reliability are valued. Wedding rings, corporate awards, memorial products, and traditional craftsmanship applications continue to favor conventional engraving methods. The timeless appeal and widespread acceptance of traditional techniques ensure their continued relevance in these market segments.

Technical Limitations and Challenges

Material Compatibility Issues

Material compatibility represents a significant consideration when choosing between holographic engraving and traditional methods. Holographic engraving requires specific material properties to achieve optimal results, including appropriate reflectivity, surface smoothness, and optical characteristics. Not all materials are suitable for holographic effects, potentially limiting application opportunities.

Traditional engraving methods offer broader material compatibility, with mechanical and laser techniques capable of marking virtually any solid material. From plastics and metals to ceramics and composites, traditional methods can be adapted to work effectively across diverse material types. This versatility makes traditional approaches more suitable for applications involving multiple material types or challenging substrate conditions.

Production Speed and Throughput

Production speed considerations vary significantly between holographic engraving and traditional methods, depending on specific application requirements and desired quality levels. Holographic engraving typically requires more time per part due to the precision requirements and complexity of pattern creation. Multiple passes and careful positioning may be necessary to achieve optimal holographic effects.

Traditional laser engraving often provides superior throughput for simple marking applications, while mechanical methods may be slower but offer advantages for deep engraving requirements. The choice between methods frequently depends on balancing production speed requirements against desired visual effects and quality standards. High-volume applications may favor traditional methods, while premium products may justify the additional time required for holographic engraving.

Future Trends and Technology Evolution

Emerging Holographic Technologies

The future of holographic engraving looks promising, with ongoing research focused on improving speed, reducing costs, and expanding material compatibility. Advanced laser systems, improved software algorithms, and novel holographic recording techniques are expected to address current limitations while opening new application possibilities. Integration with artificial intelligence and machine learning may enable automated optimization of holographic patterns for specific visual effects.

Miniaturization of holographic engraving systems and development of more affordable equipment options will likely expand market accessibility. Portable systems and desktop units may bring holographic engraving capabilities to smaller businesses and specialized applications previously limited to large industrial operations. These developments could significantly impact the competitive landscape between holographic and traditional engraving methods.

Traditional Method Improvements

Traditional engraving methods continue to evolve, with improvements in speed, precision, and automation maintaining their competitive position. Advanced CNC systems, improved cutting tools, and sophisticated software packages are enhancing the capabilities of mechanical engraving. Similarly, laser technology advances are improving traditional laser engraving speed, quality, and material compatibility.

The integration of traditional methods with digital technologies, including cloud-based design systems and automated production workflows, is improving efficiency and reducing operator skill requirements. These improvements help traditional methods maintain relevance even as newer technologies like holographic engraving gain market attention.

FAQ

What materials work best for holographic engraving compared to traditional methods

Holographic engraving works best on materials with good optical properties such as metals with reflective surfaces, certain plastics, and specially prepared substrates. Traditional methods offer much broader material compatibility, working effectively on metals, plastics, wood, ceramics, and composites. The choice often depends on whether the application prioritizes visual effects or material versatility.

How does the cost per part compare between holographic and traditional engraving

Cost per part for holographic engraving is typically higher due to longer processing times, more expensive equipment, and specialized operator requirements. Traditional engraving generally offers lower per-part costs, especially for high-volume applications. However, holographic engraving may justify higher costs through premium pricing opportunities and enhanced brand value.

Which method provides better durability for industrial applications

Traditional engraving methods typically provide superior durability for harsh industrial environments, with deeper marks and better resistance to wear and chemical exposure. Holographic engraving durability has improved significantly but may still be more vulnerable to abrasive conditions. The choice depends on specific environmental requirements and the importance of visual effects versus long-term durability.

Can holographic engraving be combined with traditional methods

Yes, holographic engraving can be combined with traditional methods to create hybrid solutions that leverage the advantages of both approaches. For example, traditional engraving might provide functional marking while holographic elements add security features or visual appeal. This combination approach is becoming increasingly popular in applications requiring both functionality and distinctive visual characteristics.

EN

EN

AR

AR

FR

FR

DE

DE

JA

JA

KO

KO

RU

RU

ES

ES