Unmatched Versatility and Material Compatibility

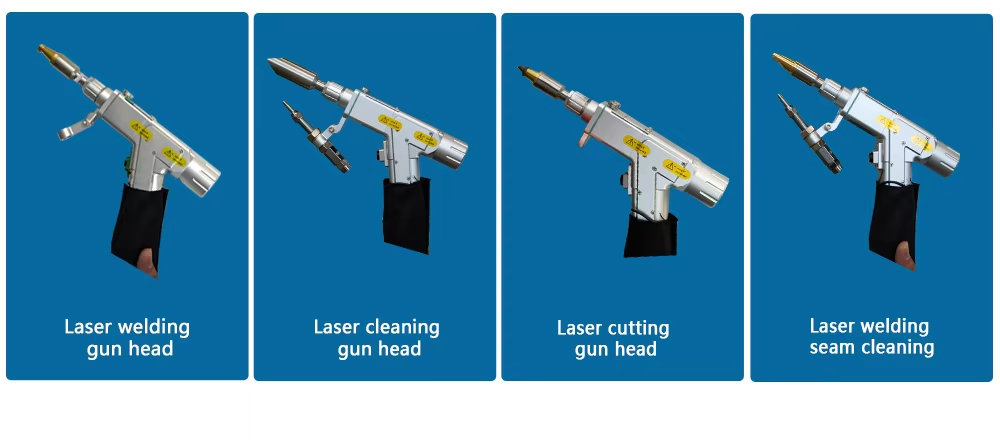

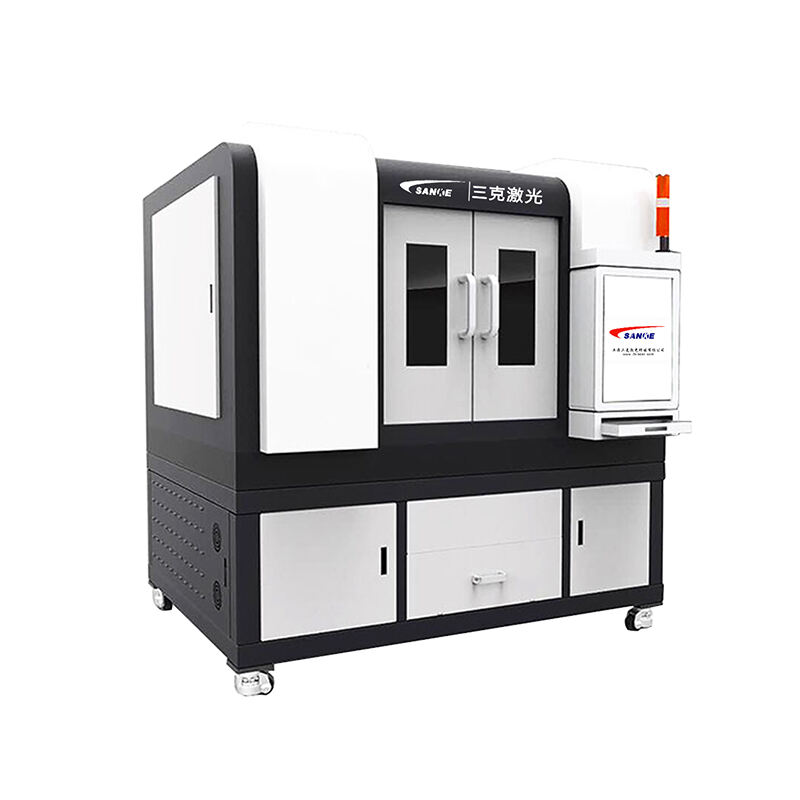

The scanlab laser demonstrates unmatched versatility and material compatibility that positions it as the ultimate solution for diverse manufacturing requirements across industries. This comprehensive adaptability stems from the system's ability to accommodate various laser sources, wavelengths, and power levels within a unified platform, eliminating the need for multiple specialized machines. The scanlab laser processes an extensive range of materials including metals, polymers, ceramics, glass, composites, and advanced materials used in cutting-edge applications. This broad material compatibility enables manufacturers to consolidate their laser processing operations around a single, highly capable system rather than investing in multiple specialized units. The scanlab laser's software-controlled parameter adjustment capabilities allow operators to optimize processing conditions for each specific material and application without hardware modifications. Advanced material databases built into the scanlab laser system provide pre-configured settings for common materials, while also allowing custom parameter development for specialized applications. This flexibility proves particularly valuable for job shops and contract manufacturers who work with diverse materials and frequently changing requirements. The scanlab laser's modular architecture supports various scan field sizes, from precise micro-processing applications requiring millimeter-scale accuracy to large-format processing covering several square meters. This scalability ensures that the scanlab laser can adapt to evolving production requirements without necessitating complete system replacement. The system's compatibility with different laser sources, including fiber, CO2, UV, and green lasers, enables optimization for specific material properties and processing objectives. Each laser type offers unique advantages for particular applications, and the scanlab laser's ability to integrate multiple source types provides unparalleled processing flexibility. Additionally, the scanlab laser supports various processing techniques including marking, engraving, cutting, welding, surface treatment, and additive manufacturing processes. This multi-functionality allows manufacturers to perform multiple operations within a single setup, reducing handling time and improving process efficiency while maintaining precise registration between different processing steps.

EN

EN

AR

AR

FR

FR

DE

DE

JA

JA

KO

KO

RU

RU

ES

ES