Mastering Precision Engineering Through Advanced Laser Cutting Technology

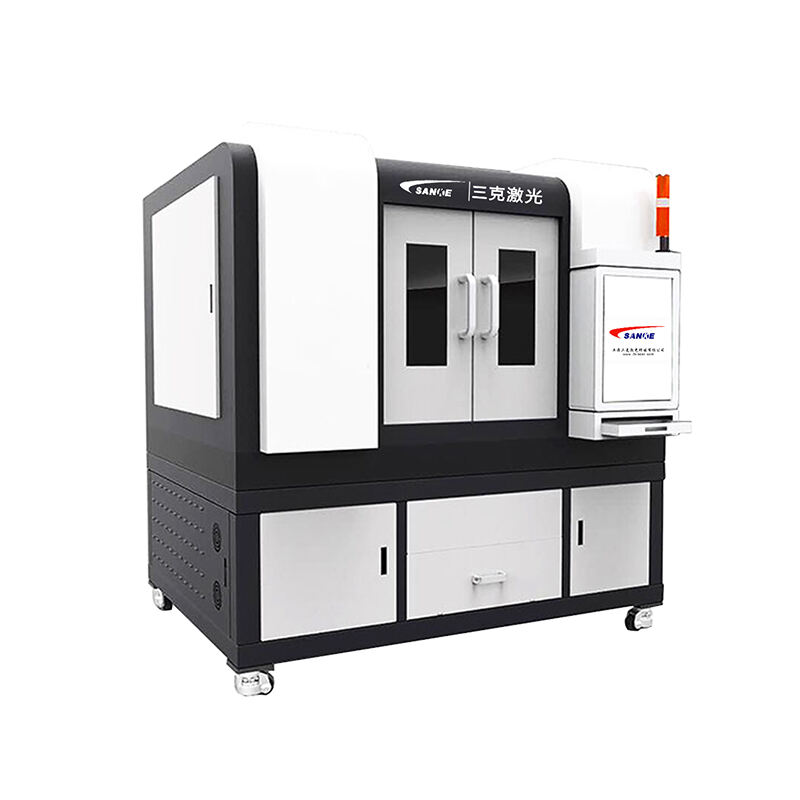

The realm of industrial manufacturing has been revolutionized by the advent of laser cutting machine technology, particularly when it comes to processing superhard materials. These sophisticated systems have transformed how we approach precision cutting, offering unprecedented accuracy and reliability in material processing. Understanding the intricate relationship between machine settings and cut quality is crucial for achieving optimal results in modern manufacturing operations.

The laser cutting machine's ability to handle superhard materials with remarkable precision has made it an indispensable tool across various industries, from aerospace to medical device manufacturing. As we delve deeper into this topic, we'll explore how different parameters interact to produce the desired outcomes and why proper configuration is essential for maintaining consistent quality standards.

Fundamental Parameters of Laser Cutting Operations

Power and Speed Settings

The relationship between laser power and cutting speed forms the cornerstone of effective laser cutting machine operation. When working with superhard materials, power settings typically range from 2000 to 6000 watts, depending on material thickness and composition. Higher power levels enable faster cutting speeds but must be carefully balanced to prevent thermal damage to the material.

Optimal speed settings vary significantly based on material properties. For instance, cutting advanced ceramics might require slower speeds of 10-30 inches per minute, while some carbide materials can be processed at higher speeds when proper power levels are maintained. The key lies in finding the sweet spot where speed and power work in harmony to produce clean, precise cuts.

Focal Point and Lens Configuration

The focal point of a laser cutting machine represents the area where laser energy concentrates most intensely. For superhard materials, precise focal point adjustment is critical - even minimal deviations can result in significant quality issues. Most modern systems employ advanced lens configurations that can be fine-tuned to maintain optimal focus throughout the cutting process.

Lens selection and positioning play vital roles in achieving desired outcomes. High-quality zinc selenide or germanium lenses, properly maintained and precisely positioned, ensure consistent beam delivery and focusing. The focal length must be carefully selected based on material thickness and desired cut characteristics.

Gas Assistance and Pressure Control

Assist Gas Selection

The choice of assist gas in a laser cutting machine significantly influences cut quality when processing superhard materials. Nitrogen, oxygen, and compressed air each serve specific purposes and affect the cutting process differently. High-purity nitrogen, for instance, prevents oxidation and produces clean, oxide-free edges on many materials.

Oxygen assist gas can enhance the cutting process through exothermic reactions, particularly useful for certain metallic materials. However, when working with sensitive superhard materials, the oxidation effect must be carefully controlled to prevent unwanted material alterations.

Pressure Optimization

Gas pressure settings directly impact cut quality and kerf width. Too little pressure results in inadequate removal of molten material, while excessive pressure can cause turbulence and irregular cutting patterns. For superhard materials, pressures typically range from 10 to 25 bar, depending on material characteristics and thickness.

Modern laser cutting machine systems often feature dynamic pressure control, allowing real-time adjustments during the cutting process. This capability ensures consistent cut quality across varying material thicknesses and geometries.

Advanced Control Features for Enhanced Precision

Pulse Width Modulation

Pulse width modulation enables precise control over the laser beam's thermal impact. By adjusting pulse duration and frequency, operators can optimize the cutting process for different sections of superhard materials. This technique is particularly valuable when dealing with varying material densities or complex geometries.

The ability to modify pulse characteristics allows for better heat management and reduced thermal stress on the material. For instance, shorter pulses with higher peak power can produce cleaner cuts in certain ceramics while minimizing the heat-affected zone.

Motion Control and Acceleration

The precision of a laser cutting machine depends heavily on its motion control system. Advanced CNC controllers manage acceleration and deceleration rates to maintain consistent cutting quality, especially around corners and intricate features. Proper acceleration settings prevent vibration and ensure smooth motion throughout the cutting process.

Modern systems incorporate sophisticated algorithms that optimize tool paths and minimize inertial effects. This results in superior edge quality and improved dimensional accuracy, particularly important when working with expensive superhard materials.

Material-Specific Considerations and Adjustments

Thermal Management Strategies

Superhard materials often require specific thermal management approaches during laser cutting. The laser cutting machine must be configured to maintain optimal temperature ranges throughout the process. This might involve implementing cooling periods or adjusting power levels to prevent thermal stress and potential material damage.

Advanced thermal monitoring systems can track heat distribution and automatically adjust cutting parameters to maintain consistent quality. This is particularly important when processing materials with low thermal conductivity or those prone to thermal shock.

Surface Quality Requirements

Different applications demand varying levels of surface finish quality. The laser cutting machine settings must be tailored to achieve specific roughness values and edge characteristics. This often involves fine-tuning multiple parameters in concert, including focus position, gas pressure, and cutting speed.

Surface quality can be further enhanced through the use of specialized assist gas mixtures and optimized nozzle designs. These modifications help achieve the desired finish while maintaining processing efficiency.

Quality Assurance and Process Monitoring

Real-time Parameter Adjustment

Modern laser cutting machine systems incorporate sophisticated monitoring tools that enable real-time quality control. Sensors track various parameters including beam characteristics, cutting speed, and material response, allowing for immediate adjustments when deviations occur.

This adaptive control capability ensures consistent cut quality even when material properties vary or environmental conditions change. It represents a significant advancement in maintaining precision across long production runs.

Quality Verification Methods

Implementing robust quality verification procedures is essential for maintaining high standards in laser cutting operations. This includes regular inspection of cut edges, measurement of dimensional accuracy, and analysis of surface finish characteristics.

Advanced inspection systems can provide immediate feedback on cut quality, allowing operators to adjust laser cutting machine settings proactively rather than reactively. This approach helps minimize waste and ensures consistent product quality.

Frequently Asked Questions

How do laser cutting machine settings affect material waste?

Optimal machine settings minimize material waste by reducing kerf width and improving cut accuracy. Proper configuration of power, speed, and assist gas parameters ensures efficient material utilization while maintaining required quality standards.

What role does maintenance play in maintaining cut quality?

Regular maintenance of laser cutting machine components, including optics cleaning, alignment checks, and nozzle inspection, is crucial for consistent cut quality. Well-maintained equipment ensures optimal performance and reliable results when processing superhard materials.

How can operators determine optimal settings for new materials?

Determining optimal settings typically involves a systematic approach of parameter testing, beginning with manufacturer recommendations and fine-tuning based on actual cutting results. Modern machines often include material databases and automated parameter suggestion systems to streamline this process.

Table of Contents

- Mastering Precision Engineering Through Advanced Laser Cutting Technology

- Fundamental Parameters of Laser Cutting Operations

- Gas Assistance and Pressure Control

- Advanced Control Features for Enhanced Precision

- Material-Specific Considerations and Adjustments

- Quality Assurance and Process Monitoring

- Frequently Asked Questions

EN

EN

AR

AR

FR

FR

DE

DE

JA

JA

KO

KO

RU

RU

ES

ES