Laser cutting has revolutionized modern manufacturing by offering unprecedented precision and versatility across countless industries. This advanced technology uses focused laser beams to cut, engrave, or etch materials with remarkable accuracy, making it an essential process for everything from automotive components to artistic creations. Understanding how laser cutting works provides valuable insight into one of today's most transformative manufacturing technologies.

The fundamental principle behind laser cutting involves generating an intense beam of light that melts, burns, or vaporizes material along a predetermined path. Modern laser cutting systems deliver exceptional results through computer-controlled precision, enabling manufacturers to create intricate designs that would be impossible with traditional cutting methods. This technology has become indispensable for industries requiring high-quality cuts with minimal waste and maximum efficiency.

Fundamental Physics of Laser Cutting

Light Amplification and Beam Generation

Laser cutting begins with the generation of coherent light through a process called stimulated emission. The laser medium, whether it's carbon dioxide gas, fiber optic cables, or crystal materials, amplifies light photons to create an intense, focused beam. This concentrated energy source forms the foundation of all laser cutting operations, providing the power needed to process various materials effectively.

The laser beam's unique properties include monochromaticity, coherence, and collimation, which allow it to maintain its intensity over long distances. These characteristics enable laser cutting systems to deliver consistent energy density to the cutting point, ensuring uniform cuts across the entire material thickness. The beam's wavelength determines its interaction with different materials, making certain laser types more suitable for specific applications.

Energy Transfer and Material Interaction

When the laser beam contacts the material surface, several physical processes occur simultaneously depending on the material properties and laser parameters. Metals typically undergo melting and vaporization, while organic materials like wood or plastic may burn or decompose. The laser cutting process carefully controls these interactions to achieve clean, precise cuts without excessive heat-affected zones.

Heat conduction plays a crucial role in determining cut quality, as excessive thermal spread can cause warping or unwanted material changes. Advanced laser cutting systems incorporate sophisticated cooling methods and optimized cutting parameters to minimize heat buildup while maintaining cutting speed and accuracy. Understanding these thermal dynamics is essential for achieving optimal results across different material types and thicknesses.

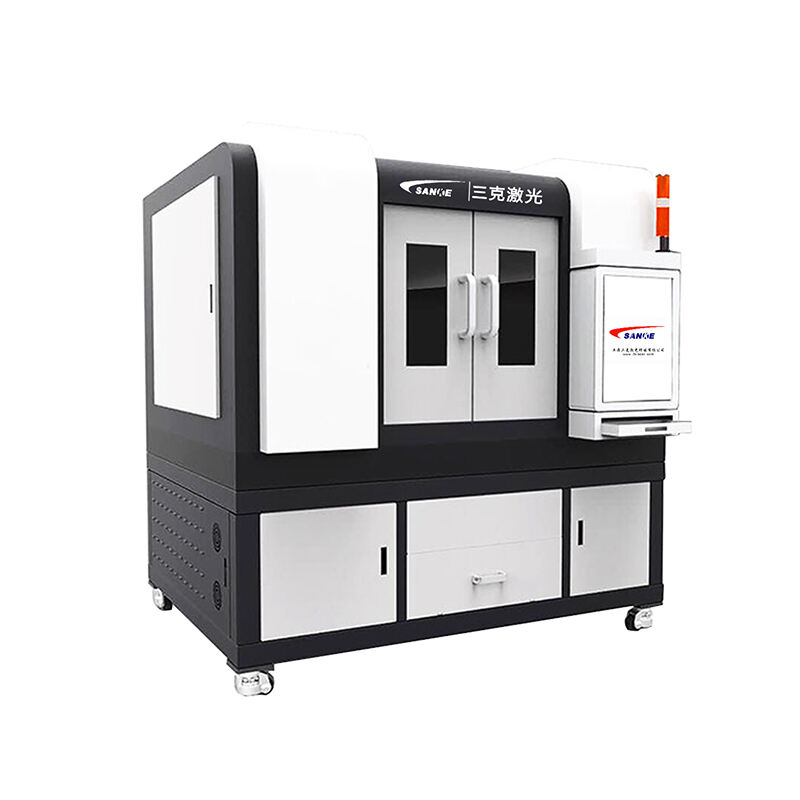

Essential Components of Laser Cutting Systems

Laser Generation Assembly

The heart of any laser cutting system is its laser generator, which produces the coherent light beam necessary for material processing. CO2 lasers use a gas mixture containing carbon dioxide, nitrogen, and helium to generate infrared light with a wavelength of 10.6 micrometers. Fiber lasers employ rare-earth elements in optical fibers to create near-infrared light, while Nd:YAG lasers utilize neodymium-doped yttrium aluminum garnet crystals for solid-state operation.

Each laser type offers distinct advantages for specific laser cutting applications, with CO2 lasers excelling at cutting non-metals and thick materials, while fiber lasers provide superior performance on thin to medium thickness metals. The choice of laser technology significantly impacts cutting speed, quality, and operating costs, making it a critical consideration for any laser cutting operation.

Beam Delivery and Focusing Systems

Efficient beam delivery systems transport laser energy from the generator to the cutting head while maintaining beam quality and intensity. Mirror-based systems use high-reflectivity mirrors to redirect the laser beam, while fiber-based delivery employs optical fibers for flexible beam routing. The beam delivery method affects system maintenance requirements, cutting head mobility, and overall system efficiency.

Focusing optics concentrate the laser beam to achieve the high power density required for effective material cutting. The focal lens diameter, focal length, and optical quality directly influence cut width, edge quality, and maximum cutting thickness. Proper focus positioning relative to the material surface is critical for optimal laser cutting performance, requiring precise control systems to maintain consistent results.

Material Processing Mechanisms

Thermal Cutting Processes

Laser cutting primarily relies on thermal processes to separate materials, with the specific mechanism varying based on material properties and processing conditions. Fusion cutting involves melting the material and using assist gas to blow away molten material, creating a clean kerf with minimal dross formation. This process works particularly well for metals and provides excellent edge quality when properly optimized.

Flame cutting combines laser heating with oxygen combustion to cut thick steel plates efficiently, though it produces wider kerfs and more heat-affected zones compared to fusion cutting. Sublimation cutting directly vaporizes material without melting, ideal for thin materials and applications requiring minimal thermal impact. Understanding these different cutting mechanisms enables operators to select appropriate parameters for specific laser cutting requirements.

Assist Gas Functions

Assist gases serve multiple critical functions in the laser cutting process, including molten material removal, combustion support, and workpiece protection. Nitrogen provides an inert atmosphere that prevents oxidation while creating high-pressure flow for material ejection, resulting in oxide-free cuts ideal for stainless steel and aluminum. Oxygen supports combustion in steel cutting, adding exothermic energy to improve cutting speeds and thickness capabilities.

Air represents a cost-effective option for many laser cutting applications, though it may produce oxidized cut edges on some materials. Compressed air systems require careful filtration and drying to prevent contamination and ensure consistent cut quality. The choice of assist gas significantly impacts both cutting performance and operating costs, making it an important consideration for laser cutting optimization.

Process Control and Automation

Computer Numerical Control Integration

Modern laser cutting systems rely heavily on computer numerical control (CNC) technology to achieve precise, repeatable results. CAD/CAM software converts design files into machine instructions that control laser power, cutting speed, and motion trajectories. This integration enables complex part geometries and automated nesting algorithms that maximize material utilization while minimizing processing time.

Advanced CNC controllers incorporate real-time feedback systems that monitor cutting conditions and adjust parameters automatically to maintain optimal performance. These systems can detect material thickness variations, focus drift, and gas pressure changes, making immediate corrections to preserve cut quality. Such automation capabilities are essential for high-volume laser cutting operations where consistency and efficiency are paramount.

Quality Control Systems

Sophisticated quality control systems monitor various aspects of the laser cutting process to ensure consistent results and identify potential issues before they affect production. Capacitive height sensing maintains proper focus positioning relative to the material surface, while power monitoring systems verify laser output stability throughout cutting operations. These monitoring capabilities enable predictive maintenance and reduce downtime.

Vision systems can inspect cut edges in real-time, measuring kerf width, dross formation, and edge perpendicularity to verify compliance with quality standards. laser cutting operations benefit significantly from these automated quality control measures, as they enable immediate process adjustments and documentation of cutting parameters for traceability purposes.

Applications Across Industries

Automotive Manufacturing

The automotive industry extensively utilizes laser cutting for producing body panels, structural components, and interior parts with exceptional precision and speed. Laser cutting enables the creation of complex geometries and tight tolerances required for modern vehicle designs while maintaining high production rates. The technology's ability to process high-strength steels and aluminum alloys makes it indispensable for lightweighting initiatives.

Tailored blanks, created by laser welding different steel grades before forming, demonstrate laser cutting's role in advanced manufacturing techniques. This approach optimizes material properties across component sections while reducing weight and improving crash performance. Laser cutting also enables rapid prototyping and small-batch production of specialized components for electric vehicles and autonomous driving systems.

Aerospace and Defense

Aerospace applications demand the highest levels of precision and material traceability, making laser cutting ideal for processing titanium, Inconel, and other specialized alloys. The technology's ability to produce burr-free edges and minimal heat-affected zones is crucial for maintaining the integrity of critical flight components. Laser cutting also enables the production of lightweight lattice structures and complex internal geometries impossible with conventional machining.

Defense contractors rely on laser cutting for armor plating, electronic enclosures, and precision weaponry components that require exact dimensional tolerances. The technology's versatility allows processing of both metallic and composite materials within the same system, streamlining production workflows. Additionally, laser cutting's computer control capabilities facilitate secure data handling and process documentation required for defense applications.

Material Considerations and Limitations

Metal Processing Characteristics

Different metals exhibit varying responses to laser cutting based on their thermal conductivity, melting point, and optical absorption properties. Mild steel cuts readily with CO2 lasers using oxygen assist gas, producing clean edges with minimal post-processing requirements. Stainless steel requires nitrogen assist gas to prevent oxidation and maintain corrosion resistance, while aluminum's high reflectivity and thermal conductivity present unique challenges for laser cutting operations.

Copper and brass require higher power densities due to their high thermal conductivity and reflectivity, making fiber lasers more suitable than CO2 systems for these materials. Titanium cuts well with laser cutting but requires careful attention to assist gas selection and cutting parameters to prevent contamination. Understanding these material-specific characteristics is essential for optimizing laser cutting parameters and achieving desired results.

Non-Metal Material Processing

Laser cutting extends beyond metals to include wood, acrylic, textiles, ceramics, and composite materials, each presenting unique processing considerations. Organic materials like wood and paper undergo thermal decomposition during cutting, requiring precise power control to prevent burning or charring. Acrylic and other plastics melt during laser cutting, necessitating specific assist gas strategies to achieve smooth, polished edges.

Textile cutting with lasers offers advantages in preventing fraying while enabling intricate patterns and rapid processing speeds for fashion and technical fabric applications. Ceramic materials require careful thermal management during laser cutting to prevent cracking from thermal stress, while composite materials may require specialized approaches to handle different fiber orientations and resin systems effectively.

Safety and Environmental Considerations

Workplace Safety Protocols

Laser cutting operations require comprehensive safety measures to protect operators from laser radiation, toxic fumes, and fire hazards. Class 4 laser systems, commonly used in industrial laser cutting, can cause severe eye and skin damage, necessitating proper beam enclosure and interlock systems. Personal protective equipment, including laser safety glasses and ventilation systems, forms the foundation of safe laser cutting practices.

Fire prevention measures are critical when processing combustible materials, requiring flame detection systems, automatic fire suppression, and emergency shutdown procedures. Regular safety training ensures operators understand proper procedures for material handling, beam path verification, and emergency response protocols. These safety considerations are integral to successful laser cutting operations and regulatory compliance.

Environmental Impact and Sustainability

Modern laser cutting systems contribute to sustainable manufacturing through reduced material waste, energy-efficient operation, and elimination of toxic cutting fluids. The precision of laser cutting minimizes kerf width and enables tight nesting patterns that maximize raw material utilization. Additionally, the clean cutting process eliminates secondary finishing operations, reducing overall energy consumption and processing time.

Fume extraction and filtration systems capture and treat emissions generated during laser cutting, preventing atmospheric contamination while enabling material recovery in some cases. The longevity and reliability of laser cutting equipment also contribute to sustainability by reducing replacement frequency and maintenance requirements. These environmental benefits make laser cutting an attractive option for companies pursuing green manufacturing initiatives.

FAQ

What materials can be processed with laser cutting technology

Laser cutting can process a wide variety of materials including metals like steel, stainless steel, aluminum, titanium, copper, and brass, as well as non-metals such as wood, acrylic, textiles, ceramics, paper, and various plastics. The specific laser type and cutting parameters must be optimized for each material to achieve the best results. Material thickness capabilities vary depending on the laser power and material properties, with some systems capable of cutting steel up to several inches thick.

How does laser cutting compare to traditional cutting methods in terms of precision

Laser cutting offers significantly higher precision than traditional mechanical cutting methods, typically achieving tolerances of ±0.1mm or better. The computer-controlled beam positioning eliminates mechanical wear and tool deflection issues common in conventional cutting. Additionally, laser cutting produces minimal kerf width, reducing material waste while enabling tight nesting of parts. The non-contact nature of the process also eliminates workpiece distortion from clamping forces.

What factors determine the cutting speed in laser cutting operations

Cutting speed in laser cutting depends on several interconnected factors including laser power, material type and thickness, assist gas pressure and type, beam focus quality, and desired edge quality. Thicker materials generally require slower cutting speeds to ensure complete penetration, while higher laser power can increase cutting speeds up to the thermal processing limits of the material. The optimization of these parameters requires experience and often involves trade-offs between cutting speed, edge quality, and operating costs.

What maintenance requirements are typical for laser cutting systems

Laser cutting systems require regular maintenance including optical cleaning, assist gas system checks, and mechanical component inspection. Laser sources typically need periodic service intervals ranging from thousands to tens of thousands of operating hours depending on the technology type. Consumable items like protective windows, nozzles, and focusing lenses require replacement based on cutting conditions and material types. Proper maintenance scheduling is essential for maintaining cut quality, system reliability, and operational efficiency in laser cutting applications.

EN

EN

AR

AR

FR

FR

DE

DE

JA

JA

KO

KO

RU

RU

ES

ES