Laser technology continues to redefine what’s possible in industrial marking. From microelectronics to medical devices, the demand for precise, fast, and permanent identification solutions has driven manufacturers to seek out smarter systems. The latest innovations in laser marking machines are not just about marking speed—they’re about intelligence, versatility, and integration.

Whether you work in aerospace, packaging, automotive, or consumer goods, the advancements in laser marking machines are making production more efficient and product traceability more reliable than ever before. But what are these cutting-edge developments, and how can they directly improve your specific manufacturing environment?

Key Technological Breakthroughs in Laser Marking Machines

AI-Powered Control Systems and Smart Feedback Loops

One of the most exciting innovations in laser marking machines is the integration of artificial intelligence and machine learning algorithms. These systems continuously monitor marking quality, surface conditions, and machine performance to make real-time adjustments.

Smart feedback loops help detect irregularities and automatically correct parameters, such as focus, power, and beam speed, without operator input. This dramatically improves first-pass yield, reducing the number of rejected products or the need for rework.

3D Surface and Curved Marking Capabilities

Traditional systems are best suited for flat surfaces, but newer laser marking machines can now handle irregular or curved surfaces using 3D scanning technology and dynamic focusing lenses. This is especially useful for industries producing cylindrical parts like pipes, medical implants, or aerospace components.

These machines adjust the laser beam’s focal length dynamically, ensuring precision even on challenging surfaces without requiring part repositioning or fixturing.

Enhanced Productivity Through Automation

Integrated Vision Systems for Auto-Alignment

Modern laser marking machines now often come equipped with high-resolution vision systems. These cameras detect part orientation, positioning, and geometry in real time. With this feedback, the machine adjusts marking placement automatically—ideal for high-speed, high-accuracy production lines.

This eliminates human error, ensures consistency, and boosts overall production speed. It also makes marking on irregularly placed or moving parts possible, streamlining automation in packaging, automotive, and electronic assembly lines.

High-Speed Galvo Systems and Multi-Axis Movement

Laser heads equipped with high-speed galvo motors are becoming the norm. These components significantly increase the scan rate and precision of the laser beam across the marking area. Some machines now offer multi-axis movement capabilities, allowing simultaneous marking on multiple sides of a part or across large-format materials without repositioning.

This advancement results in a major reduction in cycle time—an essential factor in industries where speed equals profitability.

Improved Durability, Safety, and Energy Efficiency

Solid-State and Fiber Laser Enhancements

The shift toward high-power fiber laser sources over traditional CO₂ lasers has continued, especially in applications requiring metal marking. Fiber lasers not only offer a longer operational lifespan, but they also produce higher energy efficiency and lower maintenance needs.

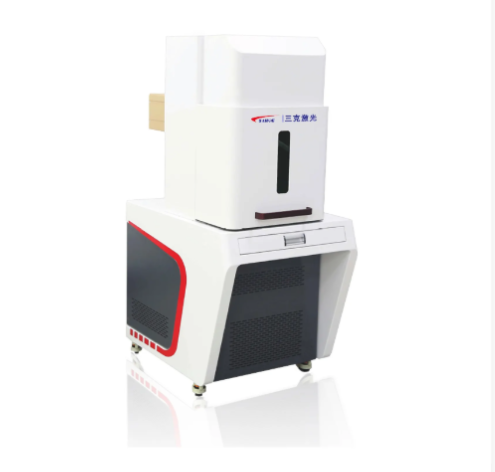

Their compact design reduces the machine footprint and cooling demands, contributing to cleaner, more space-efficient production facilities.

Enclosure and Fume Extraction Upgrades

To meet stricter environmental and safety regulations, many of today’s laser marking machines now feature upgraded protective enclosures and built-in fume extraction systems. This is particularly important for industries working with coated metals, plastics, or chemically treated parts.

These systems help keep operators safe and work environments clean, while also extending the longevity of internal components by preventing dust accumulation.

Industry-Specific Benefits of Modern Laser Marking Machines

Automotive and Aerospace

In highly regulated sectors like automotive and aerospace, where part traceability and compliance are critical, the latest laser marking machines allow for direct part marking with serialized data, barcodes, and QR codes. Advanced systems can also interface with enterprise databases, allowing for real-time verification and product tracking.

High-speed and 3D marking capabilities are perfect for engine components, fuel systems, and structural parts that require permanent identification.

Electronics and Semiconductors

In microelectronics, precision is everything. Compact laser marking machines with ultra-fine beam control can mark miniature components without damaging them. UV and green laser technology advancements enable marking on fragile plastics, PCBs, and silicon wafers.

Thanks to automated handling and vision-based alignment, even high-density part trays can be marked with minimal operator involvement.

Medical Devices and Pharmaceuticals

The healthcare industry benefits from non-contact, contamination-free marking. Recent laser marking innovations ensure UDI (Unique Device Identification) compliance on surgical tools, implants, and packaging without affecting biocompatibility.

Automated inspection and serialization help prevent counterfeiting and ensure patient safety while meeting strict regulatory guidelines.

FAQ

What makes modern laser marking machines faster and more accurate?

Advancements such as high-speed galvo motors, real-time feedback systems, and AI-powered controllers allow machines to mark faster while maintaining precision.

Can new laser marking machines be integrated into smart factories?

Yes. Most modern systems support Industry 4.0 integration, allowing connection to MES/ERP systems and data-driven production environments.

Are these advanced machines suitable for small manufacturers?

Many manufacturers now offer modular systems that scale with business size, making these technologies accessible even for small-batch or custom manufacturers.

Do new laser machines require special training?

While the technology is advanced, user interfaces have become more intuitive. Some machines even offer guided software tutorials and remote diagnostics to simplify training.

EN

EN

AR

AR

FR

FR

DE

DE

JA

JA

KO

KO

RU

RU

ES

ES