Introduction

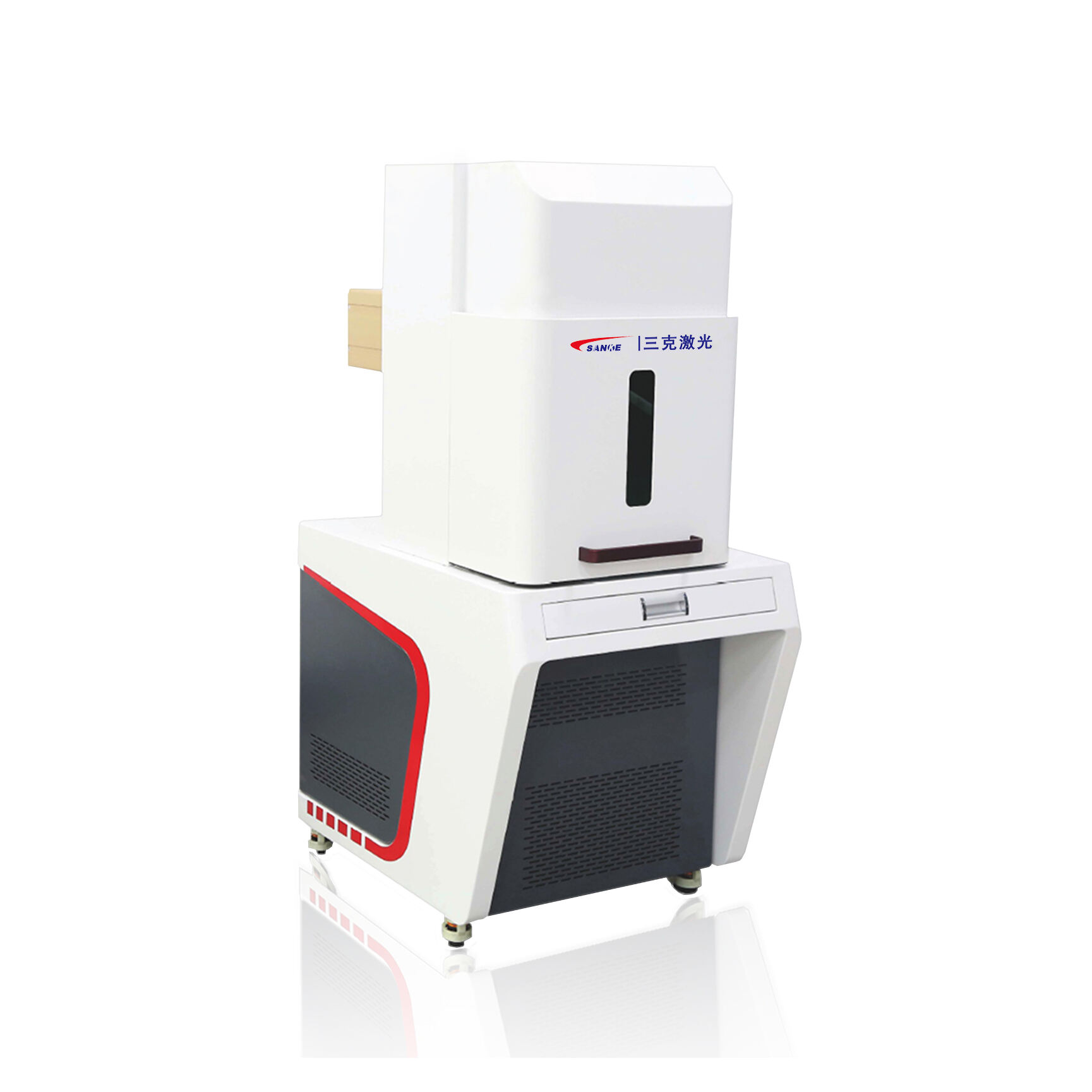

Laser marking is a key part of modern production processes and represents an ultra-precise yet also permanent method to inscribe components or parts, such as serial numbers, logos, and more. Among things that make this process versatile is of cause the diversity of laser marking machines, all varying by their own intended materials and Applications. In this post, we explain the various classes of laser marking machines and how to choose your ideal piece.

Laser Marking Machine Constituents

Different laser marking machines have their own features in the market:

Fiber Laser Marking Machines: These machines mark with fiber lasers and can be applied to a vast array of materials, such as metals, plastics and some ceramics. Fiber lasers:Marking and Deep Engraving — A fiber laser is best suitable for signs that are required to have high peak power, good beam quality suitable for high-speed marking with unsurpassed quality results.

CO2 Laser Marking Machines are best for non-metallic materials, such as wood, glass, leather and most plastics as they use a carbon dioxide gas mixture as the laser medium. They are utilized in cutting and engraving applications as well.

This type of machine utilizes ultraviolet lasers and is perfect for high-contrast marking on sensitive items such as medical devices and electronic components. For its higher cost, UV lasers provide even thinner marking lines and can be used for heat-sensitive materials without damaging them.

Greene Laser Marking Machines: These machines are used to produce reflective surfaces such as copper and gold. In addition to the aforementioned the green laser is also used for cases where precision must be very high.

YAG Laser Marking Machines: YAG lasers leave deep marks on metal surfaces and these may sometimes be made visible without any coating.

YAG: Yttrium aluminum garnet is employed for laser marking applications that need deep, long-lasting marks.

Before proceeding to the list of top best laser marking machines, lets go through some of the common factors which determine how suitable they are for your work.

When you decide to go for a laser marking machine, the following are the considerations that you should keep in mind :

Material Being Marked: Each material interacts with the various laser wavelengths in a different manner. For example, metals absorb laser energy much more efficiently at shorter wavelengths so a fiber or UV laser type is preferable. CO2 lasers are needed on the other hand for non-metallic materials such as wood and glass.

Marking Requirements The depth of marking, the required contrast and precision that the marking needs will also dictate which type of machine you need. Deeper engraving: Consider a fiber laser for deep engraving, or use UV wavelengths when you require high-contrast marks on sensitive materials.

Speed of Marking (how fast the machine marks) and Production Integration (depending upon how good fits for existing production lines, is a vital performance metric when considering manufacturing in high-volume. Fiber lasers are often more suitable for larger quantities due to their high output power.

Costs: Investment, recurring maintenance and energy costs (or operational budget). Though some machines could be more expensive upfront, their all-around value over time can be worth it considering less maintenance or energy savings.

Tips for Choosing the Best Laser Marking Machine

Determining Marking Requirements: Define what materials need to be marked, how complex the marking content is and how fast they need to produce parts with marks.

Laser Type The choice of a laser type is largely depended on the material properties and required mark depth Power A laser power that is powerful enough to achieve the desired mark.

Checking Beam Quality and Configuration: The better the beams, the higher quality marking. The machine will be configured with respect to its field of view for marking and integration possibilities.

Purchasing Equipment Stability and Reliability: Go with machines by reputable manufacturers that are known for stability, reliability, and after-sales support.

Conclusion

Laser marking machines are variety and you should choose one from following requirements of different application. Identifying the material requirements, mark quality, production expectations and budget are essential to help you choose a machine suitable for specific marking needs. Only the experts or the respective machine manufacturer should be asked – but they do not always have to know best for every type of application. Laser marking can be a great solution for improving product identification, traceability and branding in your manufacturing process if you make a proper choice of the machine.

EN

EN

AR

AR

FR

FR

DE

DE

JA

JA

KO

KO

RU

RU

ES

ES