Technical Challenges in High-Speed Laser Applications with Scanlab

High-speed laser applications pose a formidable challenge in maintaining precision, essential for processes like laser engraving and cutting. As speed exceeds 1000 mm/s, precision can drop by 10-15%, complicating tasks that require meticulous accuracy. One significant factor affecting precision is the vibration of the machinery, which can lead to inaccuracies in the laser's path. To address this, analyzing the dynamic behavior of systems is crucial to minimize errors. Advanced algorithms and technologies, such as adaptive optics, offer solutions to these precision challenges by enhancing measurement accuracy and control algorithms.

Thermal Management Challenges

Heat generation in high-speed laser cutting and engraving presents substantial thermal management challenges, influencing both material properties and cutting efficiency. Effective cooling systems, along with real-time temperature monitoring, become vital in preventing damage to the material and the laser system itself. Implementing strategies like pulsed laser technology and duty cycle management can alleviate thermal impacts, ensuring optimal operational conditions. Efficient thermal management not only preserves the integrity of the material being processed but also sustains the longevity and functionality of the laser equipment used in high-speed applications.

Scanlab Limitations Across Laser Processing Applications

Constraints in Laser Engraving and Cutting Machines

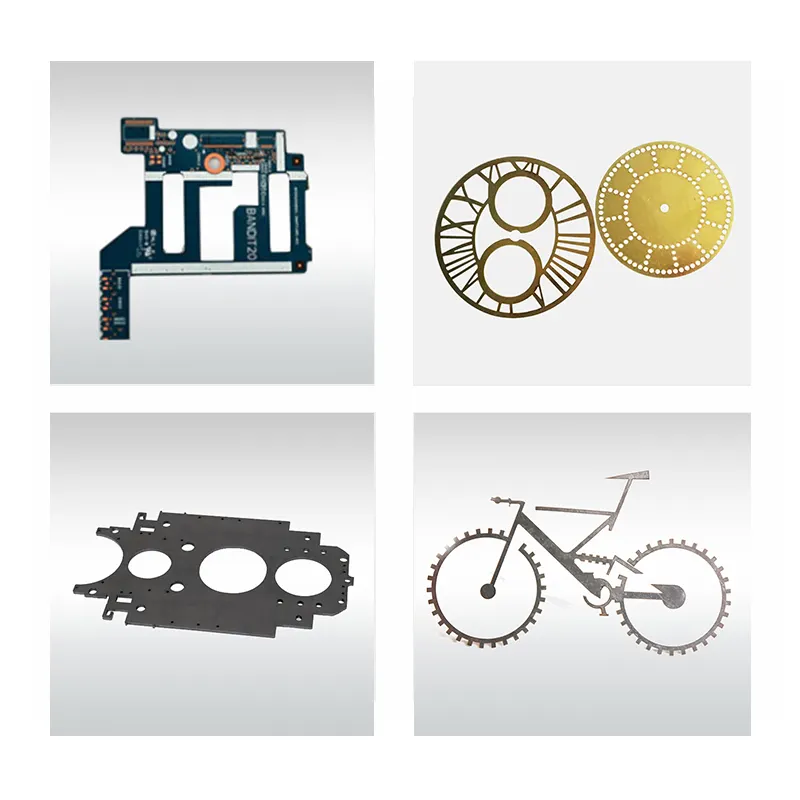

Scanlab systems, while robust and versatile, face specific constraints when applied to laser engraving and cutting machines. One significant limitation is the range of materials that can be effectively processed. For instance, certain reflective metals require specialized optics or increased power settings, which can lead to additional wear on components and reduced operational efficiency.

Addressing these challenges involves understanding these limitations so manufacturers can anticipate issues. This understanding enables the design of advanced systems that adapt to varied user requirements, ensuring consistent performance across diverse materials and applications.

Welding Machine Performance Boundaries

In laser welding applications, the performance boundaries of Scanlab systems often stem from power output and control mechanisms, directly affecting weld quality. Adjusting parameters like pulse duration and energy input is crucial for optimizing welding outcomes, but this balance can lead to inherent trade-offs between speed and joint integrity.

Real-world applications underscore the importance of input-output relationships in system configurations, which can vary significantly across materials. Manufacturers must tailor these configurations to achieve successful outcomes while navigating these performance boundaries effectively.

Operational and System Integration Challenges

Hardware and Software Compatibility Limitations

Integrating diverse hardware components with Scanlab systems often presents compatibility limitations that can lead to operational inefficiencies and increased downtime. These challenges arise due to discrepancies between different hardware and software interfaces, which are essential for the precise alignment of control systems that directly impact laser performance. For instance, if the software interface isn't compatible, it could cause misalignment in the laser systems, adversely affecting output precision. To mitigate these issues, investing in modular systems and open-source software options can provide users with the flexibility needed to overcome integration hurdles, ultimately enhancing system adaptability.

Maintenance Difficulties in Industrial Environments

High-speed laser systems, despite their efficiency, face significant maintenance challenges in industrial environments where continuous operation is crucial. Regular maintenance is vital for performance consistency, but scheduling these tasks without causing excessive downtime can be problematic. This is especially true in environments that demand high output reliability, where even minor interruptions can lead to substantial operational setbacks. Establishing preventive maintenance protocols is important, along with training in-house technicians to respond swiftly to maintenance needs. This strategy not only improves maintenance responsiveness but also helps reduce the likelihood of unexpected failures, leading to more reliable operations.

FAQ

What are the main technical challenges in high-speed laser applications?

The main technical challenges include maintaining precision and accuracy at elevated speeds, managing heat generation, and integrating hardware and software efficiently.

How does speed affect precision in high-speed laser applications?

As speed exceeds 1000 mm/s, precision can decrease by 10-15%, affecting tasks that require meticulous accuracy due to factors like machinery vibration.

What thermal management strategies are effective in laser applications?

Effective strategies include using cooling systems, real-time temperature monitoring, pulsed laser technology, and duty cycle management to prevent damage.

Which constraints do Scanlab systems face in laser processing applications?

They face material processing limitations, power output constraints in welding applications, and hardware/software compatibility issues affecting operational efficiency.

How can maintenance challenges be addressed in industrial environments?

By establishing preventive maintenance protocols and training in-house technicians, it's possible to enhance maintenance responsiveness and ensure reliable operations.

Table of Contents

- Technical Challenges in High-Speed Laser Applications with Scanlab

- Thermal Management Challenges

- Scanlab Limitations Across Laser Processing Applications

- Operational and System Integration Challenges

-

FAQ

- What are the main technical challenges in high-speed laser applications?

- How does speed affect precision in high-speed laser applications?

- What thermal management strategies are effective in laser applications?

- Which constraints do Scanlab systems face in laser processing applications?

- How can maintenance challenges be addressed in industrial environments?

EN

EN

AR

AR

FR

FR

DE

DE

JA

JA

KO

KO

RU

RU

ES

ES