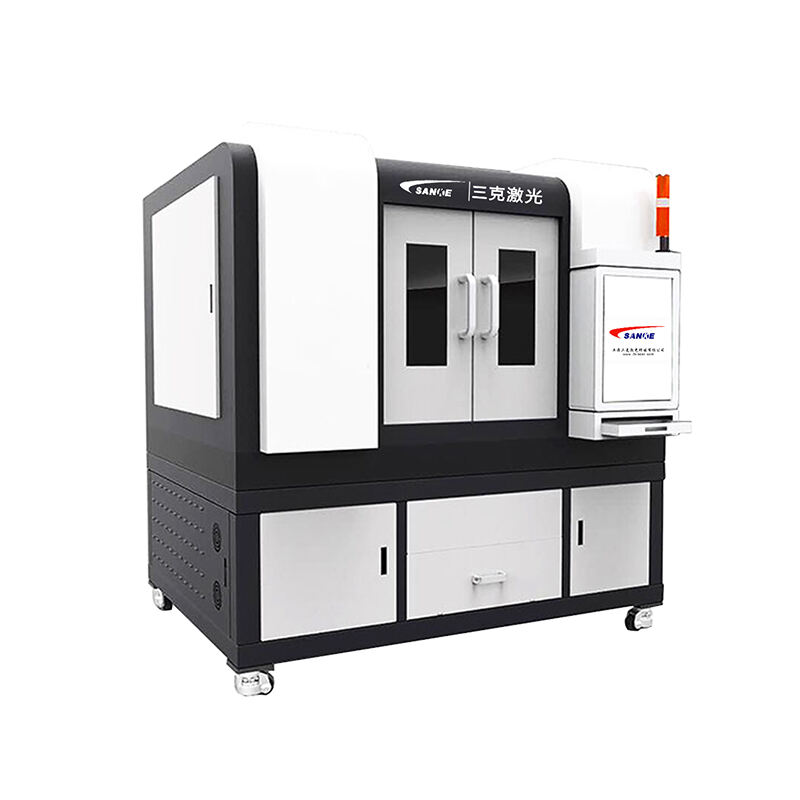

آلة قطع الليزر

تمثل آلة قطع الليزر بالألياف تكنولوجيا تصنيع متطورة تستخدم أشعة ليزر ألياف ذات طاقة عالية لقطع مختلف المواد بدقة استثنائية وسرعة فائقة. تُنتج هذه المعدات المتطورة ضوء الليزر من خلال ألياف بصرية مُشوّبة بعناصر نادرة، مما يخلق شعاعًا مركزًا بشدة يمكنه إذابة أو تبخير أو حرق المواد على طول مسارات محددة مسبقًا. تعمل آلة قطع الليزر بالألياف عن طريق توجيه شعاع الليزر عبر سلسلة من المرايا والعدسات، بحيث تتمركز الطاقة في نقطة بؤرية صغيرة تصل درجة حرارتها إلى أكثر من 10,000 درجة مئوية. وتشمل الوظائف الرئيسية لهذه الآلات المتقدمة قص الخطوط المستقيمة، والقطع التشكيلي، وحفر الثقوب، وإنشاء أنماط معقدة عبر أنواع مختلفة من المواد. وتشمل السمات التقنية أنظمة تحكم رقمية بالحاسوب تضمن التكرارية والدقة، وقدرات على التعامل التلقائي مع المواد، وأجهزة استشعار لمراقبة الوقت الفعلي، وآليات للتحكم التكيفي في القدرة. تتفوق هذه الآلات في معالجة المعادن مثل الفولاذ المقاوم للصدأ، والفولاذ الكربوني، والألومنيوم، والنحاس الأصفر، والنحاس، والتيتانيوم، وبقدرات قطع تتراوح من صفائح رقيقة جدًا إلى ألواح بسُمك عدة بوصات. وتمتد التطبيقات الصناعية لتغطي تصنيع السيارات، ومكونات الطيران والفضاء، ومعدات البناء، ووحدات الإلكترونيات، والأعمال المعدنية الزخرفية، والعناصر المعمارية. وتُحقق آلة قطع الليزر بالألياف نتائج متسقة من خلال جودة شعاع مستقرة، ومناطق مؤثورة حراريًا ضئيلة جدًا، وجودة ممتازة لأطراف القطع. وتحتوي الوحدات الحديثة على برامج ذكية تُحسّن تلقائيًا معايير القطع، مما يقلل من هدر المواد ويعظم الإنتاجية. وتتميز هذه التكنولوجيا بمرونة استثنائية في التعامل مع الأشكال الهندسية المعقدة، والأحجام الضيقة التحمل، ومتطلبات الإنتاج العالية الحجم، مع الحفاظ على الجدوى الاقتصادية مقارنةً بطرق القطع التقليدية.

EN

EN

AR

AR

FR

FR

DE

DE

JA

JA

KO

KO

RU

RU

ES

ES