Revolutionary Compact Integration Design

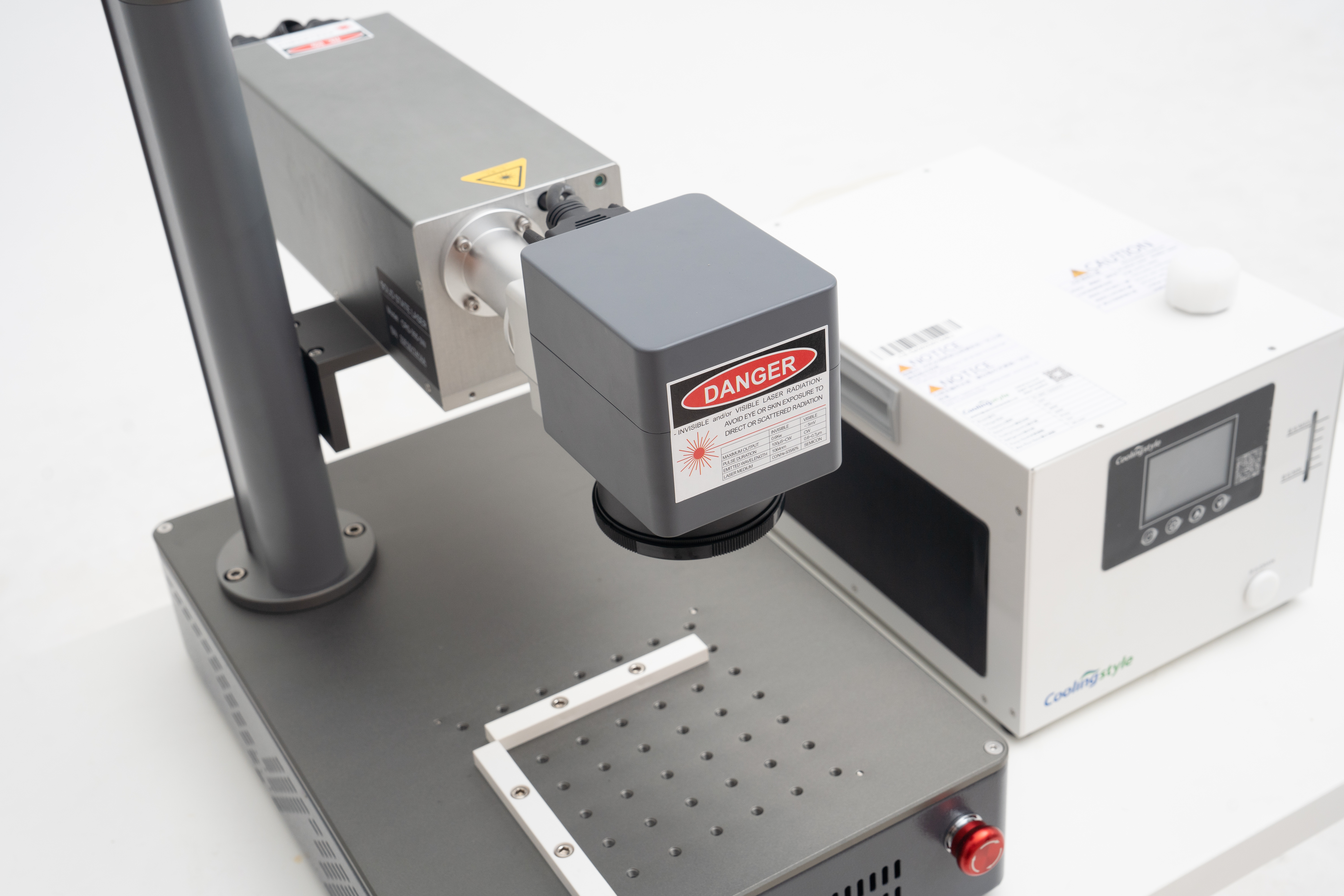

The Scanlab Basicube 10's revolutionary compact integration design fundamentally transforms how manufacturers approach laser scanning installations. Traditional scanning systems often require substantial floor space, external amplifiers, and complex wiring configurations that increase both installation costs and operational complexity. The Basicube 10 eliminates these challenges through its innovative all-in-one architecture that consolidates all essential components into a remarkably compact 185mm x 185mm x 90mm package. This breakthrough design enables manufacturers to install professional-grade scanning capabilities in previously impossible locations, maximizing valuable production floor space while maintaining full functionality. The integrated electronics eliminate the need for separate amplifier cabinets, reducing installation complexity and potential electromagnetic interference issues. Cable management becomes significantly simpler with fewer connections required, reducing installation time and improving system reliability. The compact footprint makes the Basicube 10 ideal for desktop applications, small-scale production lines, and research environments where space optimization is critical. Despite its small size, the system maintains full industrial-grade performance specifications, proving that compact design doesn't require performance compromises. The streamlined integration reduces the total number of system components, which directly translates to improved reliability through fewer potential failure points. Maintenance becomes more straightforward with all components accessible within the single compact unit, reducing service time and associated costs. The design facilitates easy system relocation when production requirements change, providing operational flexibility that traditional larger systems cannot match. This compact integration approach represents a paradigm shift in laser scanning technology, demonstrating how advanced engineering can deliver superior functionality within dramatically reduced physical constraints.

EN

EN

AR

AR

FR

FR

DE

DE

JA

JA

KO

KO

RU

RU

ES

ES