laser-Mikrobohrung

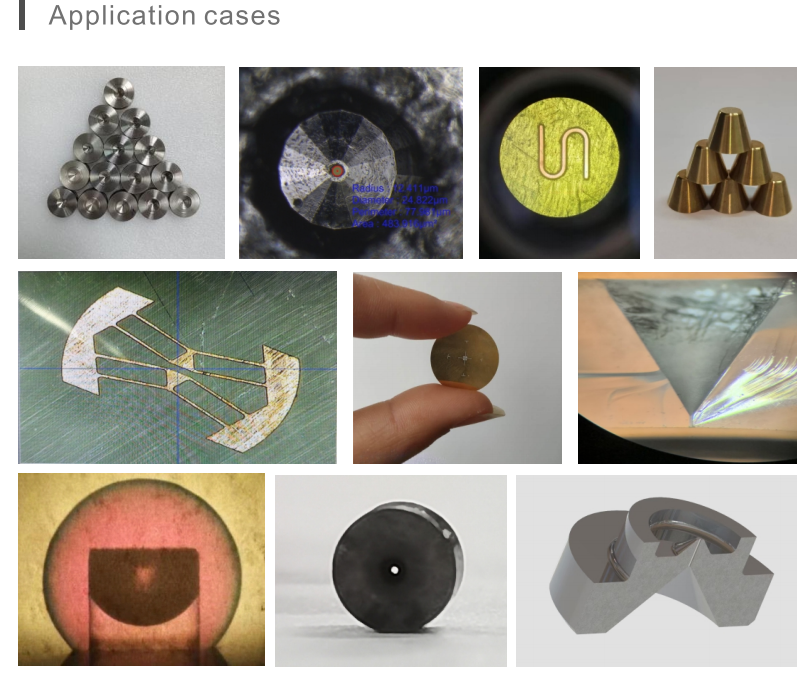

Das Laser-Mikrobohren stellt eine revolutionäre Fertigungstechnologie dar, die fokussierte Laserstrahlen nutzt, um präzise, ultrakleine Löcher in verschiedenen Materialien mit außergewöhnlicher Genauigkeit und Konsistenz zu erzeugen. Dieser fortschrittliche Prozess verwendet konzentrierte Lichtenergie, um Material zu verdampfen oder abzutragen, wodurch mikroskopisch kleine Löcher mit Durchmessern von unter einem Mikrometer bis hin zu mehreren hundert Mikrometern entstehen. Die Technologie basiert auf dem Prinzip der Photonenaufnahme, bei dem intensive Laserpulse mit der Oberfläche des Zielmaterials interagieren und dadurch eine schnelle Erhitzung und kontrollierte Materialabtragung verursachen. Moderne Laser-Mikrobohrsysteme verfügen über hochentwickelte Strahlführungssysteme, Präzisionspositioniersysteme und Echtzeit-Überwachungsfunktionen, um eine optimale Bohrleistung sicherzustellen. Zu den Hauptfunktionen des Laser-Mikrobohrens gehören die Erzeugung präziser Perforationen für Filteranwendungen, die Herstellung von Kühlkanälen in Turbinenbauteilen, die Fertigung von Öffnungen für medizinische Geräte sowie die Produktion von Belüftungssystemen für elektronische Komponenten. Technologische Merkmale umfassen die Auswahlmöglichkeiten für Wellenlängen, die Steuerung der Pulsbreite, Optionen zur Strahlformung und automatisierte Positioniersysteme, die es den Bedienern ermöglichen, auch bei großen Produktionsmengen konsistente Ergebnisse zu erzielen. Der Prozess zeichnet sich durch bemerkenswerte Vielseitigkeit beim Bearbeiten unterschiedlichster Materialien aus, darunter Metalle, Keramiken, Polymere, Verbundwerkstoffe und Halbleiter-Substrate. Die Anwendungen erstrecken sich über zahlreiche Branchen, angefangen bei der Luft- und Raumfahrt sowie der Automobilindustrie, die präzise Kühlbohrungen in Motorkomponenten benötigen, bis hin zur Herstellung medizinischer Geräte, bei denen sterile Filtration exakt definierte Porengrößen erfordert. Elektronikhersteller nutzen das Laser-Mikrobohren zur Erzeugung von Durchkontaktierungen (Vias) auf Leiterplatten, während die Textilindustrie die Technologie einsetzt, um atmungsaktive Stoffe mit gezielt gesteuerter Porosität herzustellen. Der pharmazeutische Sektor profitiert von der präzisen Lochbildung in Arzneimittelausgabesystemen und der Kapselproduktion. Forschungseinrichtungen setzen das Laser-Mikrobohren ein, um mikrofluidische Kanäle und Lab-on-a-Chip-Geräte herzustellen, die außergewöhnliche Maßhaltigkeit und Oberflächenqualität erfordern.

EN

EN

AR

AR

FR

FR

DE

DE

JA

JA

KO

KO

RU

RU

ES

ES